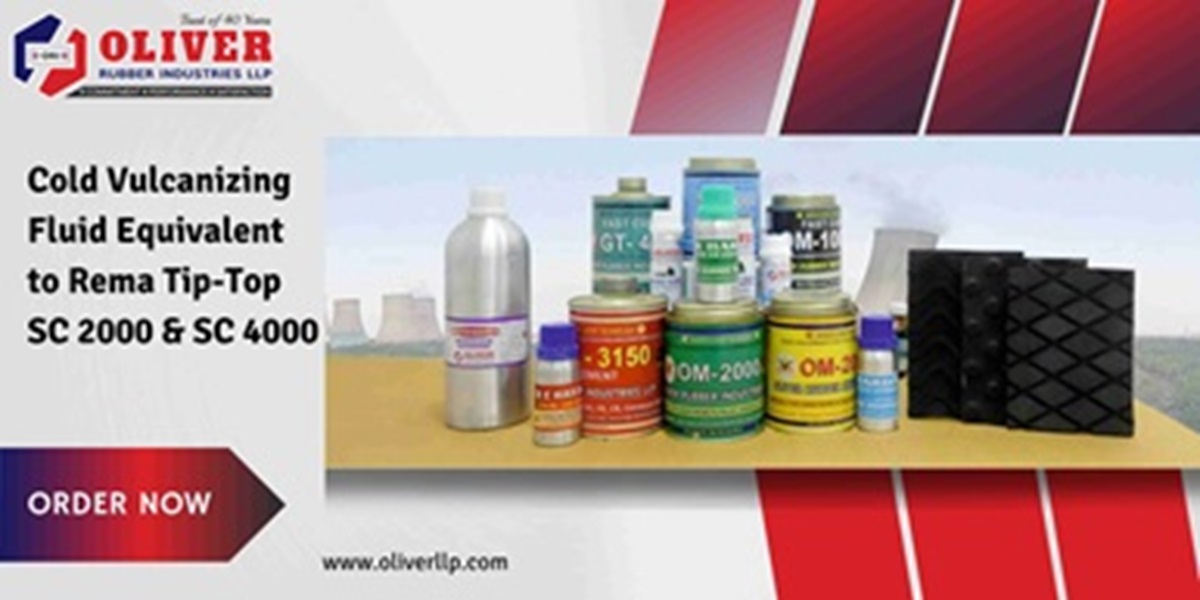

In the industrial world of conveyor belt repairs and rubber bonding, the name Rema Tip-Top SC 2000 is often regarded as a standard for cold vulcanizing adhesives. However, a new player is rising rapidly and gaining traction across global markets—Oliver Rubber A Rema Tip-Top Alternative. Known for its powerful bonding strength, reliability, and cost-effectiveness, Oliver Rubber’s OM 2000 cold vulcanizing adhesive has proven itself to be a dependable solution for industries that rely on seamless, long-lasting repairs.

The Demand for Cold Vulcanizing Solutions

Cold vulcanization is a preferred method for many industries due to its convenience and versatility. It eliminates the need for high-temperature equipment, making on-site repairs quicker, more cost-effective, and less labor-intensive. Whether in mining, automotive, manufacturing, or logistics, businesses are constantly looking for adhesives that offer quick application, strong bonding, and durability under pressure. That’s where OM 2000 Alternative of Rema Tip-Top SC 2000 comes into play.

Why OM 2000 Is Making Headlines

Oliver Rubber LLP, an India-based manufacturer of high-performance rubber bonding solutions, has developed OM 2000 to meet the growing industrial need for a reliable, cold-applied adhesive. Positioned as the OM 2000 Alternative of Rema Tip-Top SC 2000, this product is being adopted in regions like Dubai, Africa, and Southeast Asia, thanks to its excellent bonding characteristics and user-friendly application process.

Here’s why industries are making the switch:

1. Exceptional Bonding Strength

OM 2000 is engineered to deliver superior adhesion between rubber-to-rubber, rubber-to-metal, and rubber-to-fabric surfaces. It ensures a long-lasting hold, even under heavy mechanical loads and fluctuating temperatures, making it a reliable alternative for demanding environments.

2. No Heat Required

Unlike traditional vulcanization, OM 2000 requires no external heat source. The adhesive is applied at room temperature, simplifying the process and reducing downtime. This feature alone makes Oliver Rubber A Rema Tip-Top Alternative for companies seeking operational efficiency.

3. Fast Curing Time

OM 2000 sets quickly, allowing for swift repairs. In time-sensitive situations like conveyor belt breakdowns or rubber lining failures, this fast-curing property is a major advantage.

4. Durability and Resistance

OM 2000 provides excellent resistance to wear, chemicals, and weathering. It’s suitable for both indoor and outdoor applications, ensuring reliability across various climates and industrial setups.

Key Features of OM 2000 – The SC 2000 Replacement

-

Application: Cold applied at room temperature up to 60°C

-

Packaging: 1 kg adhesive with 70 grams hardener

-

Color: Green for easy application visibility

-

Shelf Life: Long shelf life when stored correctly

-

Bonding Surfaces: Suitable for rubber, metal, and fabric

These features solidify OM 2000’s position as a trustworthy OM 2000 Alternative of Rema Tip-Top SC 2000, helping industries make efficient, durable, and economical repairs.

Applications Where OM 2000 Excels

OM 2000 is not just a general-purpose adhesive—it’s built for industrial-grade applications. Some of its common uses include:

-

Conveyor Belt Splicing and Repair

Perfect for M-24 grade, DIN-X/Y/Z, and nylon-based conveyor belts, OM 2000 forms robust joints without requiring hot splicing tools. -

Pulley Lagging

Pulley surfaces require high-friction rubber lagging for performance and longevity. OM 2000 ensures secure rubber-to-metal bonding, extending pulley life. -

Tank and Pipe Lining

Its bonding strength makes it suitable for applying rubber linings in tanks, hoppers, and pipelines where chemical resistance and durability are key. -

Rubber-to-Metal Bonding

Ideal for industrial machines and structures that require the integration of rubber pads or insulations to metallic surfaces.

Why Choose Oliver Rubber?

What makes Oliver Rubber A Rema Tip-Top Alternative truly stand out is not just the quality of its product but the overall value it brings. Oliver Rubber LLP is known for:

-

Technical Expertise: Backed by years of experience in rubber technology.

-

Global Reach: Availability in markets across Dubai, Africa, and more.

-

Customer Support: Responsive service and support to assist with application and product inquiries.

-

Cost Efficiency: More affordable than Rema Tip-Top, making it a preferred choice for budget-conscious operations without sacrificing quality.

Final Thoughts

In today’s competitive industrial landscape, businesses need products that deliver consistent results, are easy to apply, and come with reliable after-sales support. OM 2000 from Oliver Rubber ticks all these boxes. As the OM 2000 Alternative of Rema Tip-Top SC 2000, it is redefining what industries expect from cold vulcanizing adhesives.

Whether you’re managing conveyor belts in a mining operation, overseeing equipment in a manufacturing plant, or handling logistics infrastructure, Oliver Rubber A Rema Tip-Top Alternative is your go-to solution for durable, efficient, and cost-effective rubber bonding.

Ready to switch to OM 2000? Contact Oliver Rubber LLP today and discover why industries in Dubai and beyond trust this SC 2000 alternative for all their cold vulcanizing adhesive needs.

0 Comments