Water Stopper: An Essential Component for Waterproofing and Leak Prevention

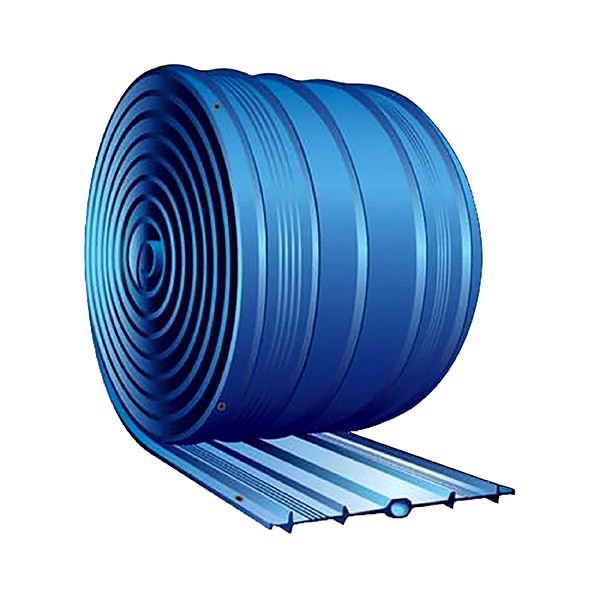

A water stopper, also known as a water bar or waterstop, is an integral part of modern construction, used primarily to prevent water infiltration in structures such as basements, tunnels, dams, swimming pools, and reservoirs. Its main purpose is to provide a seal in construction joints, ensuring that water does not seep through these joints, which could lead to severe damage to the structure over time. These products are essential for maintaining the structural integrity of buildings exposed to water or moisture, ensuring long-term durability and safety.

In this article, we will explore the various types of water stoppers, their applications, and their benefits in construction.

What is a Water Stopper?

A water stopper is a flexible, durable, and highly effective sealing solution used to prevent water from entering or exiting a specific location in a structure. It is primarily installed at the junctions of construction elements, such as joints between walls and floors or at expansion joints. Water stoppers are made from different materials, including rubber, PVC, and hydrophilic compounds, depending on the project’s requirements and the nature of the structure.

The primary function of a water stopper is to resist hydrostatic pressure, which is the pressure exerted by water when it accumulates and tries to penetrate the concrete or other construction materials. This pressure can cause cracks, leaks, and significant structural damage, making the use of water stoppers critical in preventing these issues.

Types of Water Stoppers

There are several types of water stoppers available in the market, each designed for specific applications and conditions. Some of the most common types include:

-

PVC Water Stoppers: Polyvinyl Chloride (PVC) water stoppers are among the most popular choices in construction. They are flexible, durable, and can be easily installed in various joints, including expansion joints and construction joints. PVC water stoppers are highly resistant to chemicals, ultraviolet light, and physical stress, making them ideal for applications in foundations, tunnels, and dams. These stoppers are available in various thicknesses and profiles, ensuring compatibility with a wide range of construction projects.

-

Rubber Water Stoppers: Rubber water stoppers are made from elastomeric materials and offer excellent flexibility and resistance to water, chemicals, and aging. They are commonly used in the construction of water tanks, swimming pools, and sewer systems. Rubber water stoppers are designed to withstand both dynamic and static pressure, making them suitable for structures subjected to constant water exposure. They are available in different profiles, such as “T” and “L” shapes, to meet the specific needs of a project.

-

Hydrophilic Water Stoppers: Hydrophilic water stoppers are designed to swell when exposed to water, creating a seal that prevents water from seeping through joints. Unlike traditional PVC and rubber stoppers, hydrophilic water stoppers react to moisture and expand, forming a tight bond with the surrounding concrete. This makes them particularly useful in areas where water exposure may be irregular or unpredictable. Hydrophilic water stoppers are widely used in basement constructions and other below-ground applications.

-

Metal Water Stoppers: Metal water stoppers, typically made from galvanized steel or stainless steel, are used in high-pressure applications, such as large water treatment plants, reservoirs, and tunnels. They are often combined with rubber or PVC components to enhance their sealing capability. Metal water stoppers are known for their durability and strength, making them a reliable choice for extreme conditions.

-

Composite Water Stoppers: Composite water stoppers are a combination of multiple materials, such as rubber, PVC, and metal. These stoppers offer the best of both worlds, providing superior strength, flexibility, and resistance to water and chemical damage. Composite water stoppers are often used in complex or large-scale projects where multiple sealing requirements exist.

Applications of Water Stoppers

Water stoppers are used in a wide variety of construction projects where water infiltration poses a threat to structural integrity. Some of the common applications include:

-

Basements: Basements are particularly vulnerable to water leakage due to their below-ground location. Water stoppers are used to seal joints between basement walls and floors, preventing water from entering the building. Waterproofing basements ensures a dry and safe environment for the residents and protects the foundation from moisture damage.

-

Dams and Reservoirs: In large water structures such as dams and reservoirs, water stoppers are crucial in preventing seepage that could weaken the structure. They are installed in construction joints and expansion joints to resist high water pressure and prevent leaks.

-

Tunnels: Tunnels are exposed to groundwater and can experience significant pressure from surrounding water bodies. Water stoppers are used in tunnel construction to prevent water infiltration through joints and seams. Their ability to withstand high-pressure environments makes them essential in tunnel waterproofing.

-

Swimming Pools: Swimming pools require waterproofing to maintain water levels and prevent leaks into the surrounding soil. Water stoppers are used at the construction joints of the pool structure to ensure a tight seal and prevent water seepage that could cause structural damage or undermine the pool’s foundation.

-

Sewer Systems: Water stoppers are also widely used in the construction of sewer systems to prevent the leakage of wastewater or stormwater. Proper sealing of joints in sewer pipes and chambers ensures the integrity of the system and reduces the risk of contamination.

-

Water Treatment Plants: Water treatment plants process large amounts of water, and any leakage can lead to operational problems or contamination. Water stoppers are used to prevent leaks at the joints in treatment tanks and pipelines, ensuring that the water remains contained and that the plant operates efficiently.

Benefits of Using Water Stoppers

The use of water stoppers in construction offers numerous benefits, some of which include:

-

Prevention of Water Damage: Water stoppers prevent the infiltration of water into the structure, protecting the integrity of the building. Without proper waterproofing, water can cause corrosion, mold growth, and deterioration of materials, leading to costly repairs and long-term damage.

-

Enhanced Structural Durability: By preventing water seepage, water stoppers contribute to the overall longevity of a building or structure. This ensures that the structure remains in optimal condition for many years, reducing maintenance costs and extending its lifespan.

-

Cost-Effective Solution: Installing water stoppers during the construction phase is a cost-effective solution that helps avoid expensive repairs later on. The prevention of water leaks reduces the need for water damage remediation, making it a sound investment for builders and property owners.

-

Improved Safety: Water leakage can create unsafe conditions, such as slippery surfaces or compromised foundations. By providing an effective seal, water stoppers enhance the safety of the structure for both workers during construction and residents or users after completion.

-

Easy Installation and Maintenance: Water stoppers are easy to install in construction joints and require minimal maintenance once in place. They are designed to be highly durable, with a long service life, and require little intervention after installation.

Conclusion

Water stoppers are a vital component in modern construction, providing effective waterproofing solutions that protect structures from water damage and ensure long-term durability. With a variety of materials and types available, water stoppers can be tailored to meet the specific needs of different projects, whether for residential buildings, infrastructure, or industrial applications. By investing in high-quality water stoppers, builders can ensure the integrity, safety, and longevity of their structures, preventing the costly consequences of water infiltration and ensuring that buildings withstand the test of time.

0 Comments