by icmachine | Oct 10, 2025 | Uncategorized

The rainfall type stucco applicator is a specialized machine designed to revolutionize the ceramic shell forming process by providing a uniform coating of refractory particles on patterns or “clusters”. This technology is essential for industries such as investment casting, where the quality and consistency of ceramic shells directly impact casting precision and final product integrity. The following article explores the design, functionality, benefits, and applications of rainfall type stucco applicators.

Read More: https://www.ic-machines.com/rainfall-type-stucco-applicator/

Introduction to Rainfall Type Stucco Applicators

The rainfall type stucco applicator is engineered for the precise application of sand or stucco materials onto wet slurry-coated wax clusters during the ceramic shell construction phase. Unlike conventional methods that may result in irregular coatings or material waste, this machine produces a controlled “rain” of sand, ensuring even distribution over the entire surface of the cluster. The process can be performed manually or integrated with robotic systems for enhanced automation and consistency.

How the Rainfall Stucco Applicator Works

The core mechanism of the rainfall type stucco applicator involves generating a curtain or rain of sand that falls uniformly onto the slurry-dipped cluster suspended beneath it. The cluster, usually composed of wax patterns bound together, is coated with a refractory slurry, after which it is positioned under the sand rain.

Key Steps:

-

Slurry Dip: The wax cluster is dipped into a ceramic slurry, ensuring all surfaces are wet and ready to receive the refractory material.

-

Sand Rainfall: The cluster is held under the applicator or moved through the rain curtain. Refractory sand, such as zircon or silica, rains down evenly, adhering to the sticky slurry coat exposed on the cluster.

-

Uniform Coating: Operators or automated systems rotate and manipulate the cluster to expose all surfaces, ensuring complete and uniform coverage with minimal sand usage and spillage.

Features and Design Innovations

Modern rainfall type stucco applicators, such as the RTS1000 model, include several advanced design features:

-

Uniform Rain Curtain: Ensures a full and consistent coverage with minimal waste or uneven coating.

-

Minimum Sand Consumption: Optimized design reduces the amount of expensive refractory sand required.

-

Vibration-Free Operation: The machine is engineered to minimize vibrations, which can otherwise disturb the cluster and reduce coating quality.

-

Low Spillage: Design reduces the risk of valuable material falling outside the intended area, lowering operational costs.

-

Automation Compatibility: Easily integrates with automation systems, facilitating robotic operation for high-volume manufacturing environments.

-

Maintenance-Free Performance: The applicator requires minimal upkeep, offering reliable long-term performance.

-

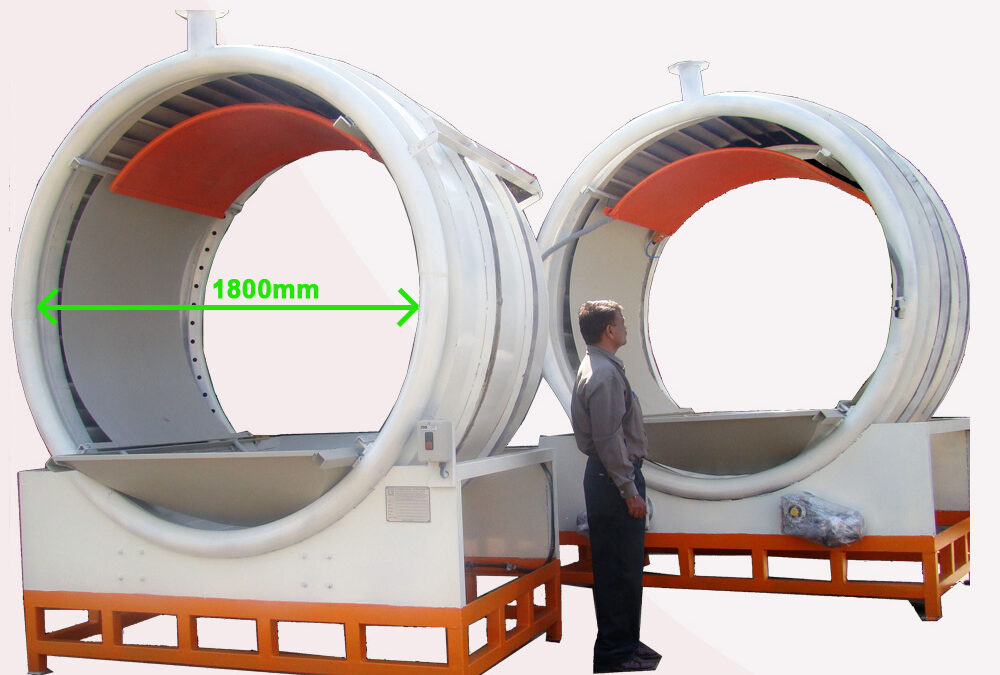

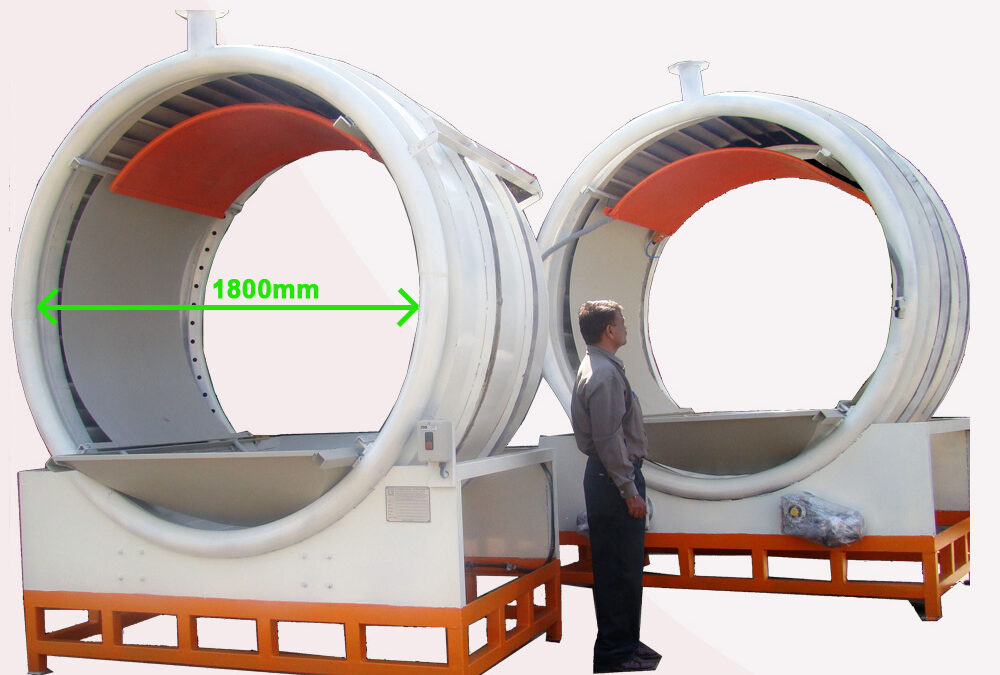

Size Options: Standard diameters of 1000mm and 1800mm accommodate diverse production needs.

Advantages Over Traditional Stuccoing Techniques

Traditional stucco application methods, such as manual hand sprinkling or tumbling, often result in variable coating thickness, increased material waste, and inconsistent shell quality. Rainfall type stucco applicators address these limitations through:

-

Consistent Coating: The rain curtain creates a repeatable, reliable process for even material distribution.

-

Material Savings: Controlled sand flow and minimal spillage mean less waste and lower costs for expensive refractory particles.

-

Reduced Labor: Automation lowers manual handling, improving safety and reducing labor costs.

-

Improved Shell Quality: Uniform particle distribution enhances shell integrity, reducing casting defects.

Applications in Industry

Rainfall type stucco applicators are widely used in the investment casting sector, particularly in foundries producing high-precision metal components for industries such as aerospace, automotive, energy, and more. The technology supports production processes that require:

-

High Repeatability: Critical for mass-produced components meeting strict dimensional tolerances.

-

Complex Geometries: Uniform sand coating allows for intricate mold shapes without thin spots or excessive coating.

-

Automation Integration: Facilitates the use of robots for moving clusters under the applicator, enabling seamless, high-volume automated shell building.

Selecting the Right Rainfall Type Stucco Applicator

Choosing a rainfall stucco applicator involves considering several factors:

-

Production Scale: Larger applicators (1800mm diameter) suit higher volume operations, while smaller machines (1000mm diameter) fit compact setups.

-

Material Type: The type and grain size of sand or refractory material must match the shell requirements for the intended casting method.

-

Degree of Automation: Facilities with existing robotics and automation infrastructure can select machines designed for automated integration.

Maintenance and Operational Efficiency

One of the standout features of modern rainfall type machines is their near maintenance-free operation. Quality applicators are built with durable materials and robust mechanical systems that withstand constant use in demanding foundry environments. Operators benefit from reduced downtime and simplified maintenance schedules, helping foundries maximize throughput and minimize costs.

Future Trends: Robotic Stucco Application

As investment casting technology advances, the integration of robotic stucco application is rapidly growing in popularity. Robots efficiently move the cluster under the applicator at precisely controlled speeds and angles, guaranteeing maximum coverage and repeatability. This trend is expected to further reduce labor, standardize shell quality, and improve process data collection for quality assurance.

Conclusion

The rainfall type stucco applicator is an innovative solution for ceramic shell manufacturing in the investment casting industry, delivering consistency, efficiency, and quality in every application. With benefits like minimal material waste, ease of automation, and robust maintenance-free operation, it has become indispensable for modern foundries seeking to optimize their shell-building process. As automation technology continues to evolve, rainfall stucco applicators will remain at the forefront of precision casting methodology.

Address –

H16, Maharashtra Industrial Development Corporation, Gokul – Shirgaon, Dist – Kolhapur, 416234 Maharashtra State, INDIA.

Our Contact :

+91 9422417760

vinaysangle@gmail.com

Visit Official Site: https://www.ic-machines.com/

by icmachine | Oct 2, 2025 | Others

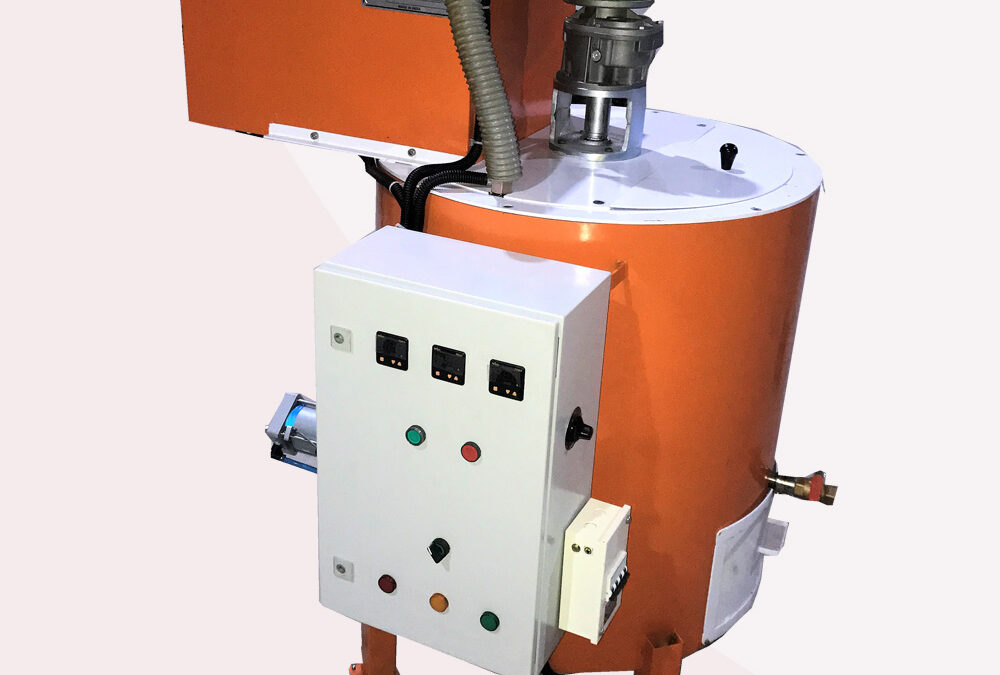

In the world of manufacturing, where precision and efficiency can make or break a production line, innovative machinery is the unsung hero. For industries reliant on wax—think candle crafting, cosmetics formulation, and even industrial packaging—one piece of equipment stands out for its simplicity and effectiveness: the Wax Melter from Lakshmi Narayan. This versatile machine isn’t just a tool; it’s a game-changer that streamlines the melting and conditioning of wax, ensuring a seamless workflow from raw slabs to ready-to-use liquid. Let’s dive into what makes this wax melter a must-have for modern operations.

Read More: https://www.ic-machines.com/wax-melter/

The Heart of the Operation: Key Features

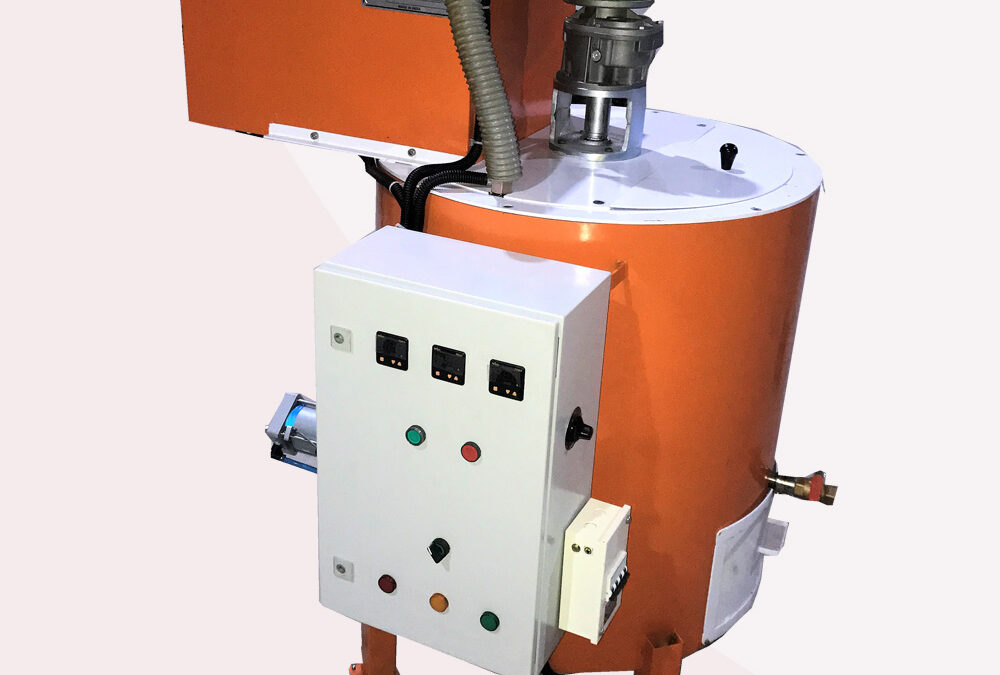

At its core, the Lakshmi Narayan Wax Melter is designed for reliability and adaptability. The system integrates several specialized components that work in harmony to handle wax with precision.

-

Drip Melting Attachment: Topped with a robust 30Kg capacity Aluminium Drip Melter, this feature is where the magic begins. Wax slabs or granules are loaded here, melting effortlessly and dripping directly into the stainless steel (SS) conditioning tank below. This gravity-fed design minimizes waste and maximizes efficiency.

-

Advanced Conditioning Tank: Once melted, the wax enters the SS tank, where it’s continuously stirred at a precise, constant temperature. This ensures a uniform blend every time—no clumping, no inconsistencies—resulting in high-quality output that’s ready for immediate use.

-

Temperature-Controlled Wax Transfer Pump: Engineered in-house, this positive displacement pump is a standout. It maintains optimal heat levels during transfer, preventing premature cooling or solidification. Paired with a heated hose, it allows for smooth, hassle-free movement of the melted wax to downstream processes.

-

Mobility and Customization: Need your melter on the move? Opt for the mobile version, complete with built-in wheels for easy relocation across your facility. Customization is key here—order with or without the slab melter, pump, or wheels, and even select your preferred conditioning tank size to fit your space and throughput needs.

These features aren’t just bells and whistles; they’re thoughtfully engineered to reduce labor, cut energy use, and boost productivity.

Specifications That Deliver

Lakshmi Narayan keeps things straightforward with specs that prioritize performance without overwhelming complexity:

-

Melting Capacity: A generous 30Kg drip melter handles substantial loads in one go.

-

Melting Rates: Choose from 10Kgs/Hr or 15Kgs/Hr models, scalable to match your production demands—whether you’re a small artisan workshop or a larger-scale manufacturer.

Built with durable materials like aluminum and stainless steel, the Wax Melter is corrosion-resistant and built to last, even in demanding environments. While exact power ratings or dimensions aren’t specified, the modular design ensures it integrates easily into existing setups.

Applications Across Industries

The beauty of the Wax Melter lies in its versatility. It’s not limited to one niche; it’s a workhorse for any process involving wax transformation.Primarily, it’s a boon for candle makers, where uniform melting ensures flawless pours and vibrant, bubble-free finishes. In the cosmetics industry, it conditions wax for lip balms, creams, and polishes, maintaining the delicate balance of heat-sensitive ingredients. Industrial users, such as those in packaging or pharmaceuticals, appreciate its ability to process paraffin or beeswax for sealing and coating applications.Whether you’re dealing with raw pellets, blocks, or specialty blends, this machine adapts, making it an essential for small-batch creators and high-volume producers alike.

How It Works: A Seamless Process

Using the Wax Melter is as intuitive as it is efficient. Here’s a step-by-step breakdown:

-

Loading: Place wax slabs or granules into the 30Kg Aluminium Drip Melter at the top of the unit.

-

Melting: Heat activates, causing the wax to liquify and drip smoothly into the underlying SS conditioning tank—no manual intervention required.

-

Conditioning: Inside the tank, automated stirring keeps the wax at a steady temperature, blending it into a homogeneous liquid.

-

Transfer: Activate the built-in pump and heated hose to pipe the conditioned wax directly to molds, mixers, or storage—clean, controlled, and contamination-free.

The entire process is temperature-monitored to prevent overheating, preserving the wax’s integrity and your end product’s quality. Setup is quick, and with optional mobility, repositioning is a breeze.

Why Choose Lakshmi Narayan? The Benefits That Count

Investing in the right equipment pays dividends in time, cost, and quality. Here’s why the Wax Melter from Lakshmi Narayan edges out the competition:

-

Uniformity Guaranteed: Continuous stirring eliminates hot spots, delivering consistent results batch after batch.

-

Efficiency Boost: Faster melting rates (up to 15Kgs/Hr) mean shorter cycle times and higher output without sacrificing safety.

-

Cost-Effective Customization: Tailor the machine to your exact needs, avoiding overkill features or unnecessary expenses.

-

Durability and Ease: Robust construction withstands daily use, while simple operation reduces training time for staff.

In an era where sustainability matters, this melter’s energy-efficient design also minimizes waste—both material and power—aligning with eco-conscious manufacturing.

Ready to Melt Away Your Challenges?

The Lakshmi Narayan Wax Melter isn’t just machinery; it’s a reliable partner in your production journey. Whether you’re scaling up operations or refining your craft, this system delivers the precision and flexibility today’s industries demand. For more details or to explore customization options, visit ic-machines.com or contact their team at H16, Maharashtra Industrial Development Corporation, Gokul – Shirgaon, Dist – Kolhapur, 416234 Maharashtra State, INDIA (Telefax: 0231-2672092).In the fluid world of wax processing, why settle for less? Melt smarter, produce better—with the Wax Melter.

WaxMelter, LakshmiNarayan, WaxProcessing, CandleMaking, CosmeticsProduction, IndustrialWax, EfficientManufacturing, WaxProduction, PrecisionMelting, CustomMachinery

by icmachine | Aug 19, 2025 | Others

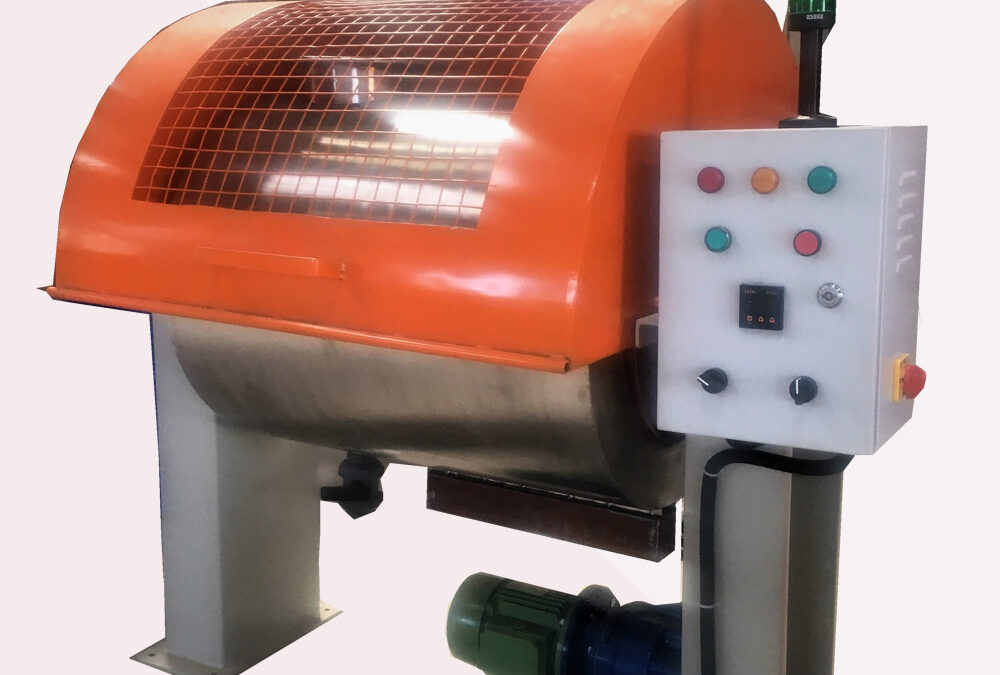

In industries such as investment casting, battery production, and ceramics, the quality of the final product hinges on the precision and consistency of the slurry used in the manufacturing process. At the heart of this critical preparation stage is the Primary Slurry Mixer, a specialized piece of equipment designed to formulate and thoroughly mix slurries with minimal effort and maximum efficiency. This article explores the role, design, and benefits of Primary Slurry Mixers, with a focus on their application in high-precision industries, drawing insights from advanced solutions like those offered by IC Machines.

For More Details: https://www.ic-machines.com/primary-slurry-mixers/

What is a Primary Slurry Mixer?

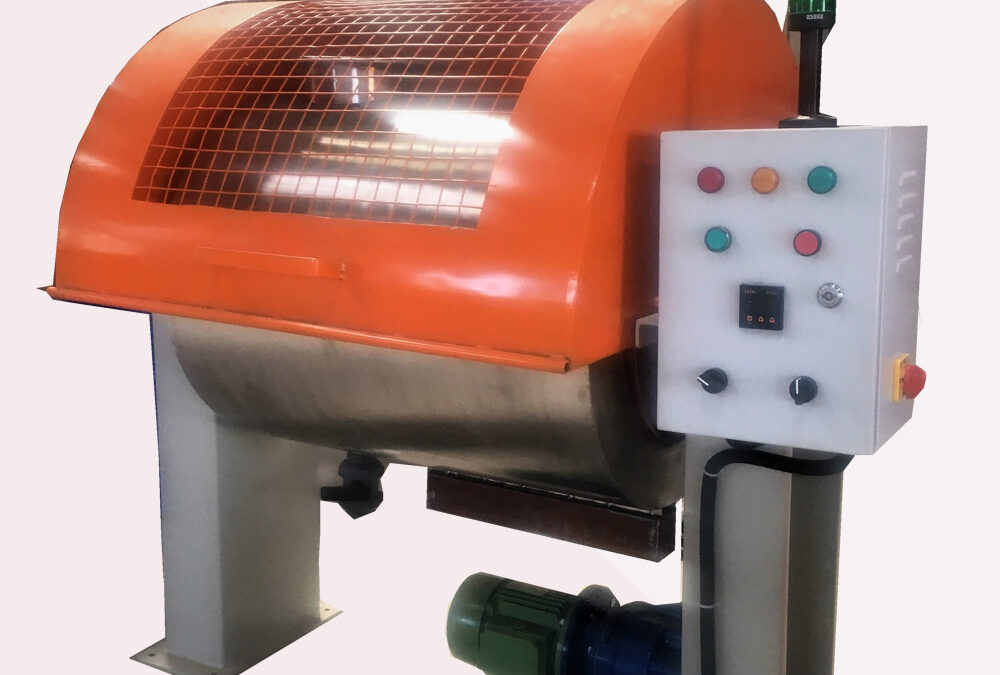

A Primary Slurry Mixer is a robust, purpose-built machine used to prepare and mix primary slurries—mixtures of liquid and solid components, such as ceramic powders, binders, and solvents. These slurries are foundational to processes like investment casting, where the quality and consistency of the slurry directly influence the quality of the final castings. The mixer ensures that the slurry achieves the desired viscosity and homogeneity without issues like heat buildup, evaporation, or foaming, which can compromise the mixture’s integrity.For example, IC Machines’ Primary Slurry Mixer is designed as a horizontal rotary barrel mixer, capable of handling slurry capacities up to 600 kg, depending on the composition. This design facilitates continuous mixing action, ensuring a uniform blend in the shortest possible time with minimal labor.

Key Features of Primary Slurry Mixers

Primary Slurry Mixers are engineered to meet the demanding requirements of industrial applications. Here are some of their standout features:

-

Horizontal Rotary Barrel Design: Unlike traditional mixers, the horizontal rotary barrel design, as seen in IC Machines’ models, ensures continuous and vigorous mixing without generating excessive heat. This prevents evaporation and foaming, preserving the slurry’s chemical and physical properties.

-

High-Capacity Mixing: With capacities ranging from small-scale laboratory mixers to large industrial units, these mixers cater to diverse production needs. For instance, IC Machines offers mixers capable of handling up to 600 kg of slurry, making them suitable for both small foundries and large-scale manufacturing.

-

Minimal Labor and Time: The automated and efficient mixing process reduces the need for manual intervention, allowing operators to focus on other tasks. This efficiency translates to faster slurry preparation, streamlining production workflows.

-

Versatility Across Industries: Primary Slurry Mixers are not limited to investment casting. They are also critical in battery manufacturing (e.g., lithium-ion battery slurry preparation), ceramics, and other applications requiring precise liquid-solid mixing.

-

Robust Construction: Built to withstand the rigors of industrial use, these mixers are typically made from durable materials like stainless steel or carbon steel with protective linings (e.g., rubber, PTFE) to resist corrosion and abrasion.

Applications of Primary Slurry Mixers

Primary Slurry Mixers are indispensable in industries where slurry quality determines the success of the final product. Here are some key applications:

-

Investment Casting: In investment casting foundries, the primary slurry forms the mold’s first layer, which directly affects the casting’s surface finish and dimensional accuracy. A consistent slurry, achieved through precise mixing, ensures high-quality castings. IC Machines’ mixers are tailored for this purpose, offering reliable performance in shell room operations.

-

Battery Manufacturing: The production of lithium-ion batteries relies on uniformly mixed slurries to create high-performance electrodes. Advanced mixers, like those from TOB Machine, ensure thorough dispersion of active materials, binders, and solvents, enhancing battery energy density and cycle life.

-

Ceramics and Materials Science: Primary Slurry Mixers are used to prepare ceramic slurries for applications like advanced ceramics and coatings. The ability to mix high-viscosity slurries without gas bubbles or inconsistencies is critical for achieving uniform material properties.

-

Chemical and Mineral Processing: In industries like mining and minerals processing, slurry mixers are used to blend materials such as alumina, iron ore, or phosphate, ensuring optimal mass transfer between solid and liquid phases.

Benefits of Using Primary Slurry Mixers

Investing in a high-quality Primary Slurry Mixer offers several advantages that enhance productivity and product quality:

-

Consistent Slurry Quality: The thorough mixing action eliminates inconsistencies, ensuring uniform particle distribution and viscosity. This is critical for applications where even minor variations can affect performance, such as in battery electrodes or casting molds.

-

Reduced Processing Time: By minimizing issues like foaming and heat buildup, these mixers enable faster slurry preparation, reducing downtime and boosting throughput.

-

Cost Efficiency: The ability to mix slurries on-site with minimal waste reduces reliance on pre-mixed materials, lowering operational costs. Additionally, the durability of these machines ensures long-term reliability, reducing maintenance expenses.

-

Enhanced Safety and Ease of Use: Features like pneumatic lifting mechanisms, explosion-proof designs, and user-friendly controls make these mixers safe and easy to operate, even in demanding environments.

-

Scalability: From laboratory-scale mixers for R&D to industrial-scale units for large production runs, Primary Slurry Mixers can be tailored to meet specific needs, offering flexibility for growing businesses.

Why Choose IC Machines’ Primary Slurry Mixers?

IC Machines stands out as a trusted provider of Primary Slurry Mixers, offering solutions that combine innovation, durability, and efficiency. Their mixers are designed specifically for investment casting and similar applications, with features like:

-

Horizontal Rotary Barrel: Ensures vigorous mixing without compromising slurry integrity.

-

Customizable Capacities: Suitable for a range of slurry volumes, from small batches to 600 kg.

-

Complementary Equipment: IC Machines offers a complete ecosystem of equipment, including slurry transfer pumps and slurry pots, for seamless integration into production lines.

By choosing IC Machines, manufacturers gain access to reliable equipment backed by years of expertise in serving investment casting and related industries.

Conclusion

Primary Slurry Mixers are more than just mixing equipment—they are critical to achieving high-quality, consistent slurries that drive success in industries like investment casting, battery manufacturing, and ceramics. With their advanced design, robust construction, and ability to deliver uniform results, these mixers streamline production, reduce costs, and enhance product quality. Solutions like those from IC Machines exemplify the innovation and reliability needed to meet the demands of modern manufacturing. Whether you’re running a small foundry or a large-scale production facility, investing in a Primary Slurry Mixer is a step toward operational excellence.

For more information on Primary Slurry Mixers and related equipment, visit IC Machines.

PrimarySlurryMixers, InvestmentCasting, SlurryMixing, BatteryManufacturing, CeramicsProcessing, IndustrialMixers, ICMachines, SlurryPreparation, ManufacturingEfficiency, HighPrecisionMixing