by arisblog | May 10, 2025 | Technology

As global concerns about energy consumption and environmental impact continue to rise, the demand for energy-efficient solutions in all sectors, including heating, ventilation, and air conditioning (HVAC), has grown exponentially. HVAC systems are critical to maintaining comfort in both residential and commercial spaces, but they can also account for a significant portion of energy use and utility costs. In recent years, technological advancements have made it possible to significantly reduce the energy consumption of HVAC systems without compromising performance or comfort. Let’s explore some of the cutting-edge innovations in energy-efficient HVAC systems – https://acjakarta.com.

1. Smart Thermostats and IoT Integration

A major advancement in HVAC technology is the emergence of smart thermostats that are connected through the Internet of Things (IoT). These thermostats not only allow for remote control and automation of temperature settings via smartphones or voice assistants, but they also learn users’ behavior patterns and adjust the settings accordingly. Smart thermostats can optimize the operation of HVAC units by adjusting the temperature based on the time of day, occupancy, and even the local weather forecast.

By allowing systems to adjust dynamically, smart thermostats help avoid unnecessary energy usage. For instance, if no one is home, the system can reduce heating or cooling until the homeowner returns. This kind of adaptability significantly lowers energy consumption without sacrificing comfort, making HVAC systems more energy-efficient than traditional models.

2. Variable Refrigerant Flow (VRF) Systems

Variable Refrigerant Flow (VRF) systems represent one of the most innovative advancements in HVAC technology. VRF systems are capable of providing both heating and cooling to different zones within a building, all through a single system. The system uses refrigerant as the cooling and heating medium, which flows at varying rates depending on the temperature demand of each individual zone.

VRF systems are especially valuable for their capacity to modulate refrigerant flow based on the unique requirements of individual zones. This results in more efficient energy use compared to traditional HVAC systems, which often cool or heat the entire building uniformly, even when some areas do not require it. As a result, VRF systems can reduce overall energy consumption by 30% or more, making them a prime choice for energy-conscious commercial and residential buildings.

3. Geothermal Heat Pumps

Geothermal heat pumps (GHPs) represent a groundbreaking and highly efficient solution in HVAC systems. Unlike conventional HVAC systems that rely on air to transfer heat, GHPs utilize the relatively constant temperature of the earth below the surface. These systems consist of a heat pump, an air delivery system (ductwork), and a heat exchanger – a system of pipes buried in the shallow ground near the building.

During the winter, the system transfers heat from the ground into the building to provide warmth, while in the summer, the process is reversed to cool the building. Geothermal heat pumps are incredibly energy-efficient because the temperature of the earth remains relatively constant, which means the system doesn’t have to work as hard as air-based systems to achieve the desired indoor temperature. As a result, geothermal systems use significantly less energy than conventional HVAC systems and have a much longer lifespan.

4. Airside Economizers

Airside economizers conserve energy by leveraging outdoor air for cooling when weather permits, thereby decreasing reliance on mechanical systems.This system is particularly effective in regions with mild to cool climates. When the outdoor air is cool enough, the economizer allows the HVAC system to use fresh air instead of the refrigeration cycle to cool the building.

This method reduces the need to run compressors, which consume a lot of energy, thus saving a significant amount of electricity. In addition, airside economizers enhance indoor air quality by supplying buildings with fresh outdoor air. As a result, this innovation is not only energy-efficient but also beneficial for the health and comfort of building occupants.

5. Inverter Technology

Inverter technology has been a game-changer in the HVAC industry. Traditional HVAC systems operate in an “on or off” mode, meaning they consume high amounts of energy when initially turned on and then cycle on and off to maintain a set temperature. In contrast, inverter-driven compressors adjust their speed to precisely meet the required load, offering more consistent performance and lower energy consumption.

The system can maintain a steady indoor temperature without the energy waste that occurs with constant cycling on and off. Inverter-driven HVAC systems are particularly efficient because they can modulate their power usage based on real-time needs, providing cooling and heating more efficiently. This technology is now a staple in modern air conditioning and heat pump systems and contributes significantly to overall energy savings.

6. Advanced Insulation and Ductwork Design

Efficient HVAC systems aren’t just about the technology; they also depend on the infrastructure surrounding them. Advanced insulation materials and high-quality ductwork** play an essential role in enhancing the energy efficiency of HVAC systems. Insulation materials such as spray foam, reflective barriers, and improved fiberglass can reduce the loss of conditioned air, ensuring that the system doesn’t have to work harder to maintain the desired temperature.

Likewise, high-efficiency ducts that minimize air leakage are crucial in ensuring that the system delivers the intended airflow without wasting energy. When these advancements in insulation and ductwork are integrated into an HVAC system, the overall efficiency improves, reducing energy consumption and utility costs.

Conclusion

As energy efficiency becomes a growing priority across the globe, the HVAC industry continues to innovate in ways that offer both environmental and financial benefits. Whether it’s smart thermostats, VRF systems, geothermal heat pumps, or airside economizers, these innovative solutions are reshaping modern approaches to heating and cooling in buildings. By integrating advanced systems and infrastructure, buildings can achieve optimal comfort while drastically reducing their energy consumption. As these technologies continue to evolve, the future of HVAC looks not only more efficient but also more sustainable for generations to come.

by arisblog | May 10, 2025 | Education

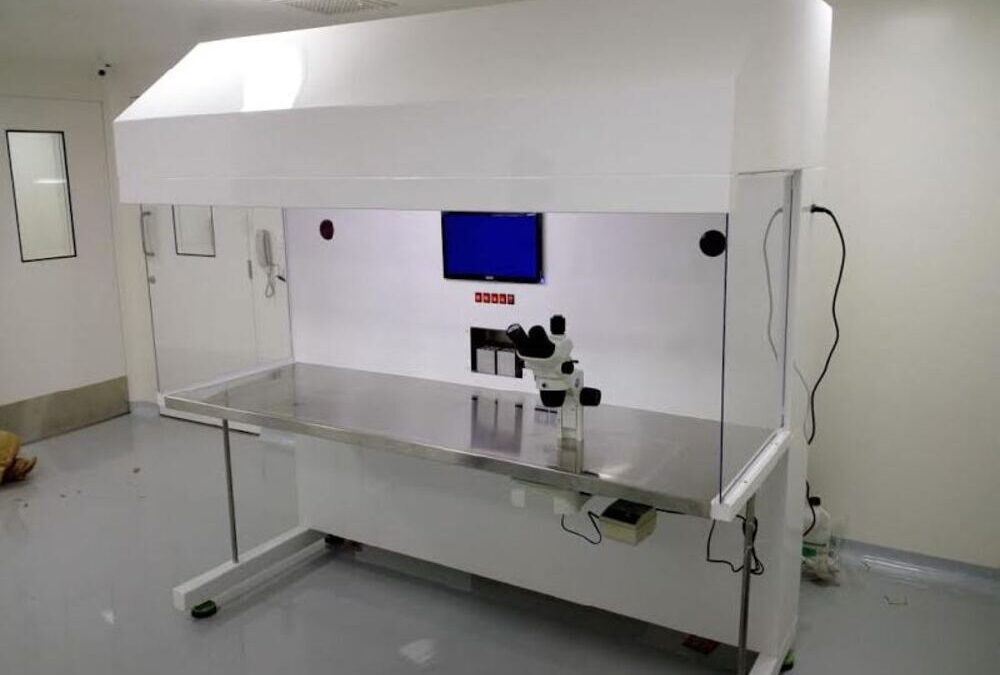

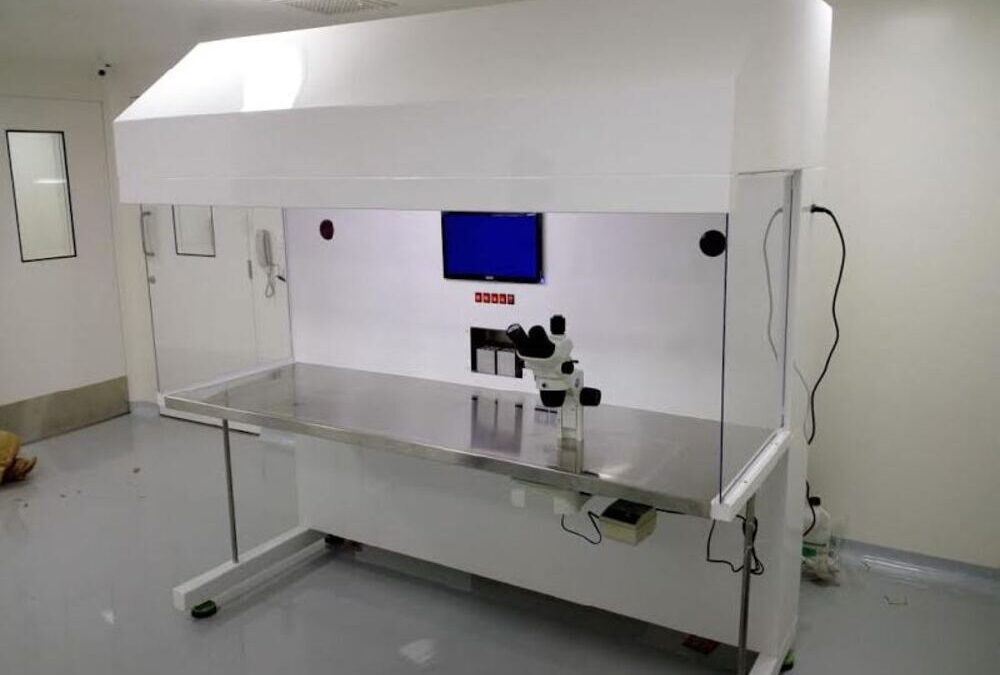

In modern laboratories, maintaining a contamination-free environment is crucial for the accuracy and reliability of experiments. This is especially true for Polymerase Chain Reaction (PCR) laboratories, where even the smallest contamination can lead to inaccurate results, waste time, and lead to costly errors. One of the most important pieces of equipment for maintaining such a sterile environment is the laminar flow hood. In this article, we will explore the significance of laminar flow hoods, their operation, and their role in PCR laboratory workstations.

What is a Laminar Flow Hood?

A laminar flow hood, also known as a laminar flow cabinet, is a vital tool used in laboratories to provide a clean and sterile workspace. These hoods use a continuous stream of filtered air to create a barrier against airborne contaminants, ensuring that particles, such as dust, bacteria, and other pathogens, do not interfere with sensitive experiments. The filtered air is directed in a smooth, unidirectional flow—known as laminar flow—across the workspace to prevent contamination.

There are two primary types of laminar flow hoods: horizontal flow and vertical flow. In horizontal flow hoods, air is pushed from the back of the unit and flows toward the operator, while in vertical flow hoods, the air flows from the top of the unit down to the workspace. Both types of hoods serve the same primary function, but the choice between horizontal and vertical flow depends on the type of work being performed and the specific needs of the laboratory.

Role of Laminar Flow Hoods in PCR Laboratories

Polymerase chain reaction (PCR), a method for replicating DNA segments, plays a fundamental role in molecular biology, microbiology, and numerous diagnostic procedures. However, PCR is extremely sensitive to contamination, particularly from DNA or RNA from other sources that may inadvertently interfere with the reaction. This is where laminar flow hoods come into play, as they are integral in maintaining a contamination-free environment for PCR experiments.

PCR requires a delicate balance of various reagents and precise conditions for successful amplification. A laminar flow hood ensures that the workspace remains sterile, reducing the risk of contaminants interfering with these critical conditions. In a PCR laboratory, the laminar flow hood serves several important functions:

1. Protection of Samples: Laminar flow hoods provide a controlled environment where PCR samples can be handled without the risk of contamination from external particles. The constant airflow prevents airborne contaminants from settling on the work surface or the sample itself.

2. Protection of the Operator: Laminar flow hoods also protect the laboratory technician working in the space. The hoods are designed to prevent any airborne contaminants from escaping the unit and spreading into the laboratory environment. This is particularly important in PCR experiments, where even small amounts of contamination can render results invalid.

3. Ensuring Accuracy of Results: By providing a clean, controlled workspace, laminar flow hoods help ensure the accuracy and reliability of PCR results. Contaminants, such as bacteria, fungi, or even foreign DNA, can negatively affect the outcome of the amplification process. A laminar flow hood is an essential tool for minimizing such risks.

How Laminar Flow Hoods Work

Laminar flow hoods operate by drawing air through high-efficiency particulate air (HEPA) filters. The filters remove particles from the air, ensuring that only clean, sterile air is introduced into the workspace. Once the air passes through the HEPA filters, it flows in a smooth, unidirectional pattern across the work surface.

The airflow is designed to create a barrier between the operator and the sample. In horizontal flow hoods, the air moves towards the operator, providing a shield that protects the workspace from contamination. In vertical flow hoods, the air flows downwards, creating a sterile work surface below.

The filtered air in the hood creates an environment where particles from the outside world are less likely to enter. However, the operator must follow specific procedures to maintain the sterile conditions inside the hood. This includes wearing protective gloves, regularly cleaning the workspace, and ensuring that no non-essential items are brought into the hood.

Best Practices for Using Laminar Flow Hoods in PCR Laboratories

To ensure that a laminar flow hood provides maximum protection for PCR work, operators must adhere to certain best practices:

1. Regular Maintenance and Filter Replacement: The HEPA filters in laminar flow hoods should be replaced regularly to ensure optimal airflow and contamination control. As time passes, filters may accumulate debris, diminishing their efficiency.

2. Proper Technique: Operators should be trained in proper laminar flow hood usage techniques. This includes placing materials in the correct orientation, avoiding rapid movements that can disrupt airflow, and ensuring that items used inside the hood are sterile before introduction.

3. Routine Cleaning: The workspace inside the hood should be cleaned regularly with appropriate disinfectants to maintain a sterile environment. Any spills or residues from reagents should be cleaned immediately to prevent contamination.

4. Avoid Overloading the Hood: Laminar flow hoods are designed to handle a specific volume of air and equipment. Placing excessive objects in the workspace can obstruct airflow and compromise the performance of the hood.

Conclusion

Lemari Asam: Laminar flow hoods are an essential component of PCR laboratory workstations, offering a controlled, contamination-free environment that is vital for the success of PCR experiments. They ensure the integrity of samples, protect operators from exposure to harmful agents, and minimize the risk of contamination that can compromise the accuracy of results. By following proper maintenance and usage guidelines, laboratories can ensure that their laminar flow hoods continue to provide reliable protection for their PCR workflows, ultimately contributing to the success of their research and diagnostic efforts.

by arisblog | Mar 28, 2025 | Household

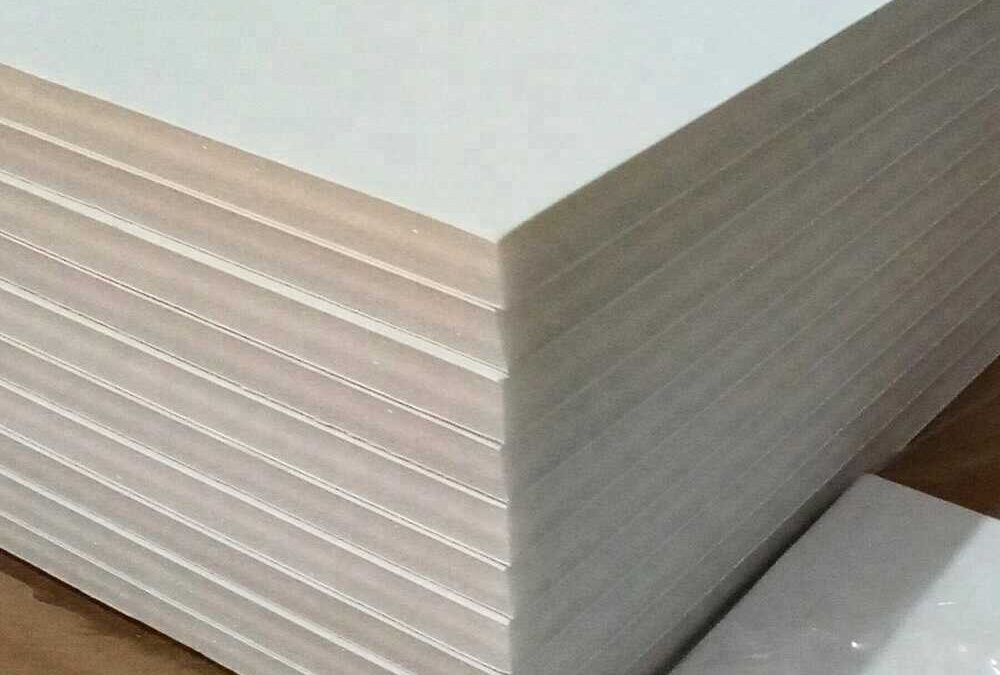

When it comes to modern construction and home improvement, materials play a pivotal role in achieving durability, aesthetics, and cost efficiency. Among these, High-Density PVC Foam Boards have emerged as a versatile and reliable option for various applications. Whether you’re designing interiors or constructing exteriors, these boards provide unique benefits that can elevate your project – gstarboard.com.

In this article, we’ll delve into the essential aspects of High-Density PVC Foam Boards, including their composition, advantages, applications, and practical tips for usage. Let’s explore why they should be on your radar for your next building or home improvement endeavor.

What Are High-Density PVC Foam Boards?

High-Density PVC Foam Boards are engineered panels made from polyvinyl chloride (PVC). They consist of a lightweight foam core sandwiched between durable PVC outer layers, offering a combination of strength, flexibility, and low weight. The “high-density” designation signifies that these boards are sturdier and more compact than their standard counterparts, making them ideal for demanding applications in construction and design.

Key Features and Benefits

1. Durability

High-Density PVC Foam Boards are highly resistant to moisture, rot, and corrosion, ensuring longevity even in challenging environments. This makes them an excellent choice for applications exposed to humidity or outdoor conditions.

2. Lightweight

Despite their robust structure, these boards are remarkably lightweight, making them easy to transport, handle, and install.

3. Versatility

Available in various sizes, thicknesses, and finishes, High-Density PVC Foam Boards can be customized to suit specific project needs. They are compatible with cutting, drilling, and painting, allowing for tailored applications.

4. Cost-Efficiency

Compared to traditional materials like wood or metal, PVC Foam Boards offer a more affordable alternative without compromising on quality or functionality.

5. Eco-Friendly

Many manufacturers are prioritizing sustainability, producing boards that are recyclable and free from harmful chemicals.

Applications in Home and Building Projects

1. Interior Design

High-Density PVC Foam Boards are widely used for cabinetry, shelving, and wall paneling. Their smooth surface can be painted or laminated to match any aesthetic, providing a sleek and modern finish.

2. Exterior Applications

For outdoor projects such as cladding, signage, or fencing, these boards shine due to their weather-resistant properties. They can withstand prolonged exposure to sunlight and rain without warping or degrading.

3. Furniture and Fixtures

Their lightweight yet sturdy composition makes them ideal for crafting furniture, display units, and other fixtures that demand both form and function.

4. Advertising and Signage

The smooth surface and customizable options make them popular for creating vibrant, durable signs and displays.

Practical Tips for Using High-Density PVC Foam Boards

1. Choose the Right Thickness: Depending on your project, select boards with appropriate thickness to ensure structural integrity and aesthetic appeal.

2. Cut with Precision: Use sharp tools for cutting and shaping the boards to achieve clean edges and accurate dimensions.

3. Secure Properly: When installing, use appropriate adhesives or fasteners to ensure stability and avoid damage to the material.

4. Avoid Excessive Heat: While these boards are heat-resistant, prolonged exposure to high temperatures may affect their integrity. It’s best to avoid placing them near heat sources.

5. Regular Cleaning: Maintain the boards’ appearance by gently cleaning with a soft cloth and mild detergent.

Why High-Density PVC Foam Boards Are the Future of Building Materials

As the demand for sustainable, versatile, and cost-effective building materials continues to grow, High-Density PVC Foam Boards stand out as a forward-thinking choice. Their ability to combine durability, adaptability, and affordability positions them as a game-changer in the home and building industry.

Whether you’re a professional builder or a DIY enthusiast, integrating High-Density PVC Foam Boards into your projects can unlock new levels of creativity and efficiency. Their wide range of applications, coupled with their long-lasting performance, makes them a smart investment for anyone focused on quality and innovation.

By understanding the potential of High-Density PVC Board, you can make informed decisions that benefit both your budget and your project’s outcome. Their unique properties ensure that they remain an integral part of modern construction and design.

by arisblog | Mar 28, 2025 | Household

Proper tool maintenance is essential for ensuring longevity, optimal performance, and workplace safety. Whether you are a DIY enthusiast or a professional in the construction industry, keeping your tools clean and rust-free can save you money and prevent unexpected breakdowns. This guide covers everything you need to know about cleaning, preventing rust, and removing corrosion from your tools – tokohasil.com.

The Importance of Tool Maintenance

Tools are an investment, and regular care extends their usability while maintaining efficiency. Dirty, corroded, or neglected tools can compromise work quality and even pose safety hazards. Implementing a consistent tool care routine helps prevent damage, reduces repair costs, and ensures smooth operation.

Cleaning Your Tools: Best Practices

Dirt, grease, and debris can accumulate on tools over time, leading to wear and tear. Cleaning tools after each use prevents buildup and preserves their condition.

Hand Tools

Wipe down after use: Use a dry or slightly damp cloth to remove dirt and dust.

Deep cleaning: For stubborn grime, use mild soap and water with a scrub brush. Dry thoroughly afterward.

Lubrication: Apply a light coat of oil to moving parts to prevent friction and wear.

Power Tools

Dust removal: Use compressed air to clear vents and crevices.

Check moving parts: Remove any lodged debris to prevent mechanical failure.

Electrical components: Wipe cords and inspect for damage to ensure safety.

Metal Tools and Blades

Use solvent cleaners: Remove grease and oil buildup with a degreaser or isopropyl alcohol.

Sharpening: Keep cutting tools sharp to maintain efficiency and precision.

Storage considerations: Keep blades dry to prevent moisture exposure.

Rust Prevention: Keeping Your Tools Corrosion-Free

Rust is one of the biggest threats to metal tools. Preventing rust formation is easier than removing it once it develops.

Proper Storage

Keep tools dry: Store tools in a moisture-free environment. Use silica gel packets or a dehumidifier in humid areas.

Toolboxes and cabinets: Opt for rust-proof tool storage solutions that provide insulation against moisture.

Hang tools when possible: Keeping tools off the ground prevents moisture absorption.

Protective Coatings

Apply oil or wax: A thin layer of machine oil or paste wax provides a protective barrier against rust.

Use rust inhibitors: Anti-rust sprays or silica-based coatings help prevent oxidation.

Bluing treatment: Some professionals opt for a chemical bluing treatment to add a corrosion-resistant layer.

Routine Maintenance

Check tools regularly: Inspect for early signs of rust and address them immediately.

Use tools frequently: Regular use prevents moisture buildup and corrosion.

Avoid prolonged exposure to water: Dry tools immediately if they get wet.

Rust Removal: Restoring Your Tools

If rust does develop, it is crucial to remove it before it spreads and damages the tool.

Mechanical Methods

Wire brush: A sturdy wire brush can scrub off light surface rust.

Sandpaper or steel wool: Use medium to fine-grit sandpaper to remove rust without damaging the tool surface.

Power tools: For extensive rust, use a grinder or rotary tool with a wire wheel attachment.

Chemical Methods

Vinegar soak: Soaking tools in white vinegar for a few hours loosens rust for easy scrubbing.

Baking soda paste: A mix of baking soda and water applied to rusted areas can help break down oxidation.

Commercial rust removers: Phosphoric acid-based removers are effective for severe corrosion.

Electrolysis Method (For Heavily Rusted Tools)

For severe rust, electrolysis is a powerful method.

1. Fill a plastic container with water and add baking soda.

2. Attach the rusted tool to the negative terminal of a battery charger.

3. Use a sacrificial piece of metal on the positive terminal.

4. Submerge both in the solution and let the process run for several hours.

This method effectively removes deep rust without damaging the tool’s integrity.

Conclusion

Regular tool care is an essential practice for homeowners, DIYers, and professionals in the construction and building industries – baut dan mur. Implementing a cleaning routine, preventing rust, and knowing how to remove corrosion can significantly extend the life of your tools. By investing time in proper maintenance, you ensure efficiency, safety, and cost savings in the long run.

With these practices in place, your tools will remain reliable, durable, and ready for any task at hand. Take care of your tools, and they will take care of your work!