by agnisteels | Jul 14, 2025 | Technology

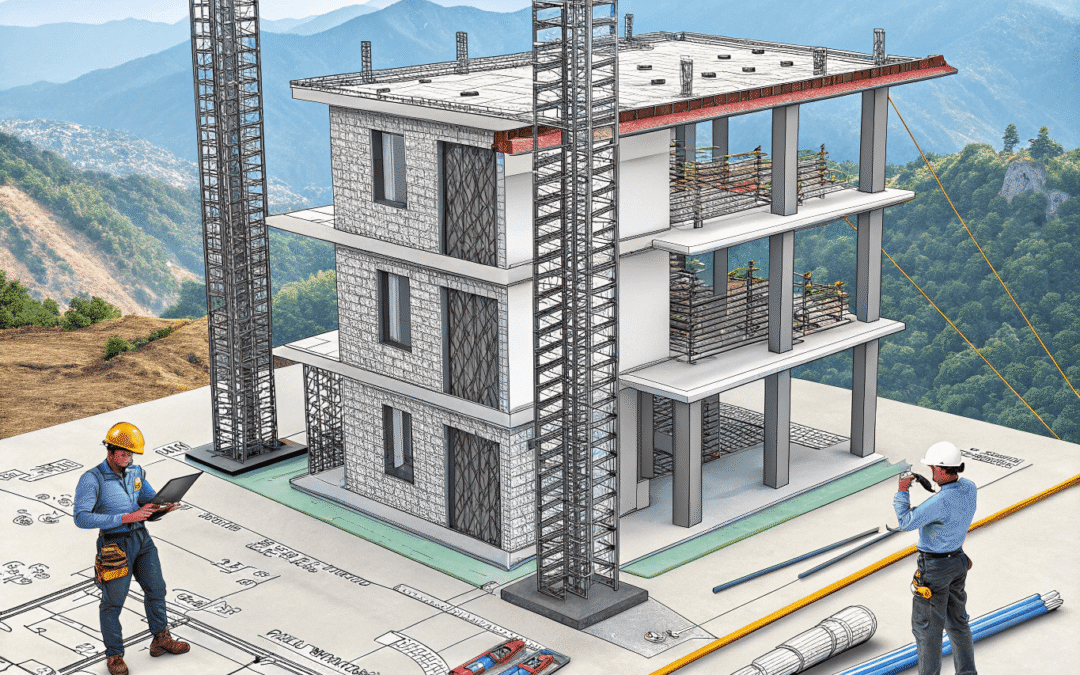

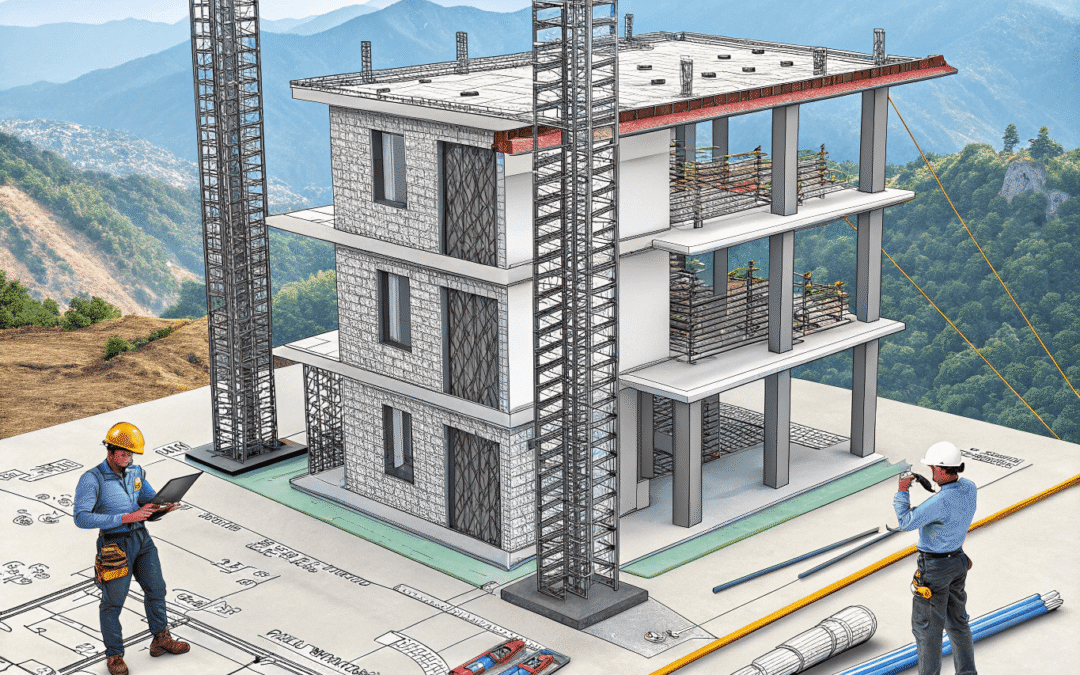

India’s infrastructure growth is accelerating at an unprecedented pace. From highways and metro rail systems to smart cities and high-rise apartments, strong foundations are critical. And when it comes to RCC construction, no component is as essential as TMT bars — especially 550 Grade TMT bars.

Whether you’re a builder, architect, or an individual homeowner, choosing the right steel grade can make or break your project’s strength, cost-efficiency, and lifespan.

What Makes Fe 550 TMT Bars Stand Out?

Fe 550 Grade TMT bars are engineered to withstand extreme pressure, making them ideal for large-scale construction projects. With a minimum yield strength of 550 N/mm², these bars ensure better load handling without increasing the steel quantity.

But there’s more:

-

Low carbon content makes welding and fabrication easier

-

Consistent bendability, perfect for complex RCC designs

-

Corrosion-resistant, ideal for coastal and humid zones

-

Fe 550D variant adds extra ductility, making it earthquake-safe

Why RCC Construction Demands Quality Steel

RCC relies on the synergy of concrete and steel. While concrete handles compression, it’s the steel that manages tensile forces. Weak or low-grade steel can compromise the entire structure — that’s why civil engineers recommend Fe 550 or Fe 550D bars for long-lasting strength.

How to Choose the Right TMT Bars Manufacturer in India

With dozens of brands in the market, picking the right one can be tricky. Trusted TMT bars manufacturers in India like Agni Steels offer:

-

ISI-certified, BIS-approved Fe 550D TMT bars

-

Advanced TEMPCORE technology for uniform strength

-

On-site testing and quality control

-

Excellent customer support and dealer network across India

Real Applications of Fe 550 TMT Bars

-

Multistorey apartments & villas

-

Metro and highway projects

-

Bridges, flyovers, and ports

-

RCC retaining walls and water tanks

Conclusion

Strong structures begin with strong steel. If you’re looking to build safely, efficiently, and with long-term confidence, 550 Grade TMT bars from a reliable manufacturer like Agni Steels are your best bet.

by agnisteels | Jul 8, 2025 | Technology

In a country like India, where many regions fall under seismic zones, building structures that can withstand earthquakes is not just important — it’s essential. One of the most critical components in earthquake-resistant construction is the TMT bar. Known for their strength and flexibility, TMT bars (Thermo-Mechanically Treated bars) form the backbone of safe structural design in seismic-prone areas.

In this blog, we explore why TMT bars are vital for earthquake-resistant buildings, how they perform under seismic stress, and what to look for when choosing the right steel reinforcement for your project.

Understanding Earthquake Forces

Before we delve into how TMT bars help, it’s important to understand how earthquakes impact structures. During seismic activity, ground motion causes a building’s base to move in different directions. This creates tensile and compressive forces throughout the structure. If a building cannot absorb or redistribute these forces, it may crack, collapse, or suffer severe damage.

What Makes TMT Bars Ideal for Earthquake Zones?

1. High Ductility

Ductility refers to a material’s ability to undergo deformation without breaking. During an earthquake, buildings need to bend and flex slightly to absorb shock without breaking. Fe 550D and Fe 600 TMT bars, in particular, offer superior ductility, which allows them to stretch under seismic force and return to their original form once the load is released.

2. Excellent Bend and Re-bend Properties

TMT bars are manufactured using a special quenching and tempering process that ensures they can be bent and shaped as required — without cracking. This flexibility helps in maintaining the integrity of the building even when subjected to tremors.

3. High Tensile Strength

TMT bars combine compressive strength from concrete with their own tensile strength, resulting in a composite material that is resistant to both types of stress. This is a key factor in withstanding the lateral forces generated during earthquakes.

4. Strong Bonding with Concrete

TMT bars have uniform and well-designed rib patterns that firmly grip the surrounding concrete, ensuring the two materials act as one. This reduces the chances of slippage during sudden movements caused by earthquakes.

Grades of TMT Bars Suitable for Seismic Zones

The Indian Standard Code (IS: 1786) recommends Fe 550D and Fe 500D grades for earthquake-prone regions. The “D” denotes ductility, which is crucial in seismic resistance. These grades offer a balanced combination of strength and flexibility, ensuring buildings can absorb seismic shocks without structural failure.

Why Ordinary Bars Are Not Enough

Many small-scale builders still use mild steel or lower-grade bars for budget reasons. However, these materials:

-

Lack the necessary ductility

-

Have poor resistance to repeated stress cycles

-

Do not form strong bonds with concrete

This compromises the structural integrity of buildings and increases the risk of failure during an earthquake.

Real-Life Examples of TMT Bars Saving Lives

In the aftermath of several earthquakes in India and around the world, studies found that buildings constructed with high-quality TMT bars and proper RCC frameworks remained intact, while others without such reinforcements suffered major damage or collapse. This has led to mandatory use of earthquake-resistant materials in many municipal building codes.

Tips for Builders and Homeowners

-

Never compromise on steel quality. Choose ISI-certified TMT bars from reputed manufacturers.

-

Use Fe 550D or higher grades for constructions in seismic zones.

-

Follow proper construction codes and structural design guidelines.

-

Ensure adequate concrete cover to protect steel from corrosion and fire.

-

Consult a structural engineer to determine the exact quantity and placement of steel bars.

Advantages of Using Agni Steels’ TMT Bars in Earthquake Zones

At Agni Steels, we manufacture Fe 550D TMT bars that are engineered to perform in India’s most challenging seismic environments. Our bars offer:

-

High elongation for superior flexibility

-

Exceptional tensile and yield strength

-

Uniform rib patterns for excellent concrete grip

-

100% billet-based manufacturing for purity and consistency

-

ISI & ISO certifications ensuring national and international compliance

Whether you’re constructing in a metro city or a rural village within a seismic zone, Agni Steels’ TMT bars offer the peace of mind and safety you need.

Building the Future with Safety in Mind

Earthquakes are unpredictable, but the safety of a building can be planned. With modern materials like TMT bars and intelligent structural design, you can minimize risks and protect lives. It’s no longer just about building — it’s about building resilient structures that stand strong through the tests of nature.

Whether you’re a homeowner, builder, architect, or engineer, the message is clear: TMT bars are not optional — they are essential.

Final Thoughts

As urbanization continues and high-rise developments become the norm, it’s time to build not just upward, but stronger and smarter. TMT bars, particularly Fe 550D and Fe 600 grades, play a vital role in making buildings earthquake-resistant.

Don’t wait for a disaster to think about safety. Choose the right materials from the start — and when in doubt, always consult experts and certified manufacturers like Agni Steels, where every bar is built with precision, tested for performance, and trusted across South India.

by agnisteels | May 29, 2025 | Household

In the ever-evolving world of construction, the materials we choose play a vital role in ensuring the strength, safety, and longevity of structures. Among these materials, TMT (Thermo-Mechanically Treated) bars stand out as a cornerstone of modern building practices. When it comes to strength and durability, 550 Grade TMT bars have gained immense popularity for their exceptional mechanical properties and superior performance.

In this blog, we’ll explore what makes 550 Grade TMT bars ideal for construction and why they should be your top choice for residential, commercial, and infrastructure projects.

What Are 550 Grade TMT Bars?

550 Grade TMT bars refer to Thermo-Mechanically Treated reinforcement bars with a minimum yield strength of 550 megapascals (MPa). The number 550 represents their stress resistance level, making them stronger than Fe 415 and Fe 500 bars. These bars are ideal for structures requiring higher load-bearing capacity, seismic resistance, and long-term stability.

Key Features of 550 Grade TMT Bars

-

High Yield Strength

-

With a yield strength of 550 MPa, these bars can handle significant stress before deforming. This makes them perfect for high-rise buildings, bridges, flyovers, and dams.

-

Superior Elongation

-

Corrosion Resistance

-

Earthquake Resistance

-

Fire Resistance

Advantages of Using 550 Grade TMT Bars

1. Cost Efficiency

Though slightly more expensive than lower-grade bars, their higher strength means fewer bars are needed, reducing overall material costs.

2. Long-Term Durability

TMT 550 bars resist corrosion, fatigue, and wear, increasing the lifespan of structures and reducing long-term maintenance expenses.

3. Versatility

These bars are suitable for a wide range of construction projects, from small homes to massive industrial complexes.

4. Better Bonding with Concrete

Their ribbed pattern ensures strong bonding with concrete, reducing the risk of slippage and enhancing structural integrity.

Applications of 550 Grade TMT Bars

-

High-Rise Buildings: Stronger reinforcement for taller structures

-

Bridges and Flyovers: High stress resistance

-

Marine and Coastal Structures: Superior corrosion resistance

-

Industrial Infrastructure: Withstand heavy machinery loads

-

Commercial Complexes and Malls: Enhanced safety and durability

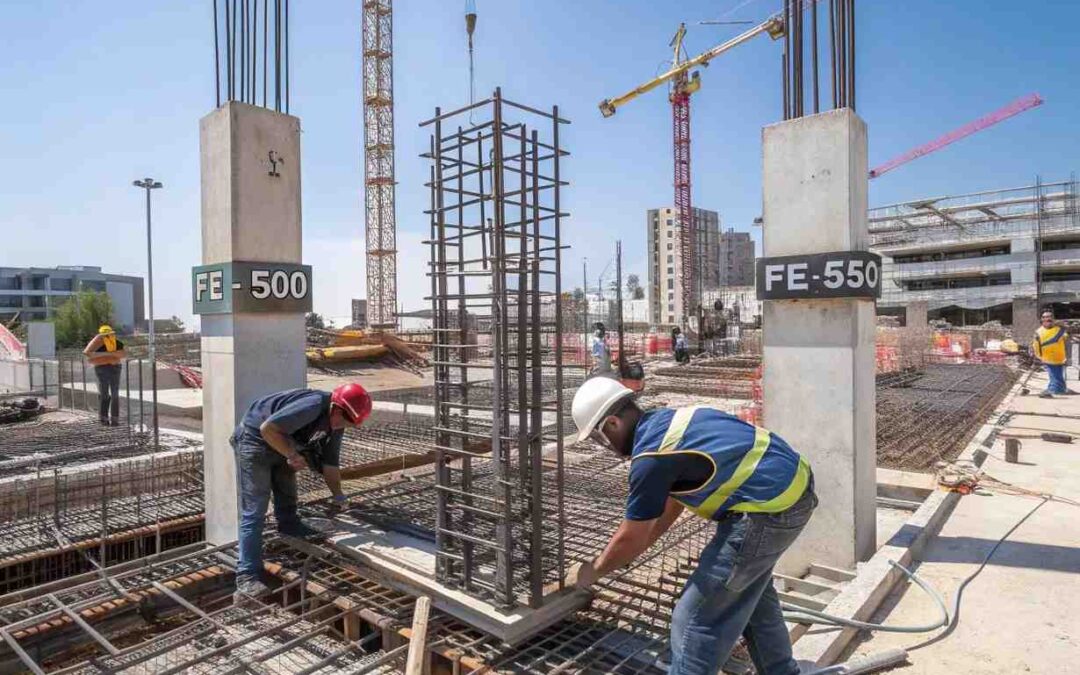

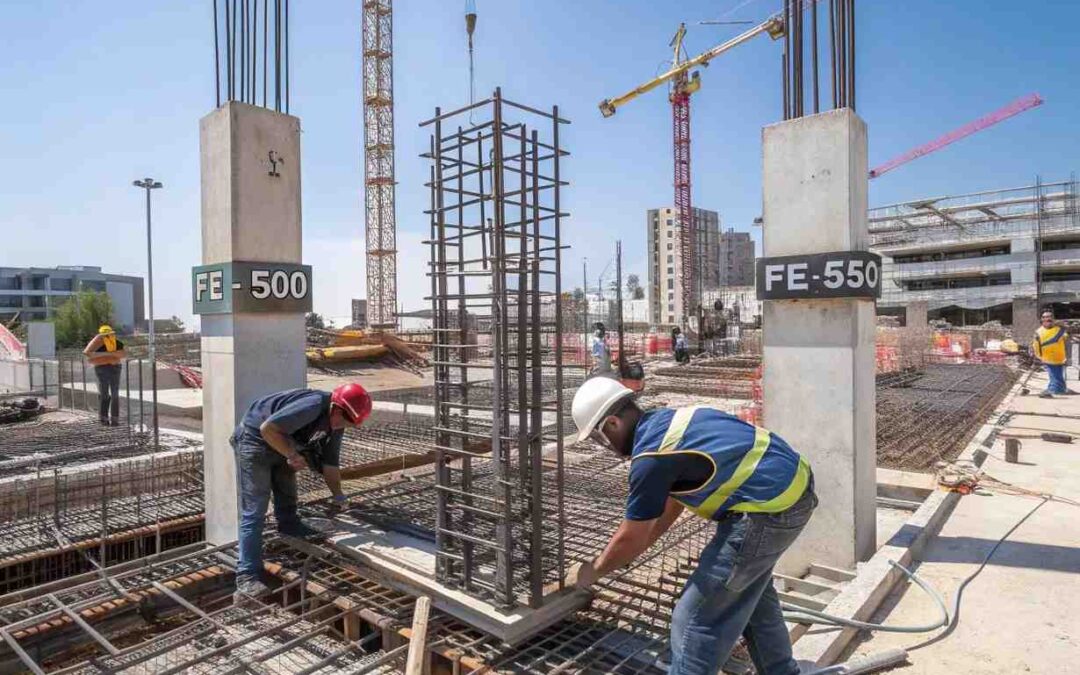

550 vs 500 Grade TMT Bars: What’s the Difference?

| Property |

Fe 500 TMT Bars |

Fe 550 TMT Bars |

| Yield Strength |

500 MPa |

550 MPa |

| Elongation (%) |

Higher |

Slightly Lower |

| Cost |

Moderate |

Slightly Higher |

| Use Case |

General |

Heavy-duty |

| Earthquake Zones |

Suitable |

Ideal |

Fe 550 offers higher strength and durability, whereas Fe 500 provides better flexibility. Your choice depends on the structural requirement.

How to Choose the Right 550 Grade TMT Bars

-

Certification: Look for ISO, BIS, or ISI-certified bars for quality assurance.

-

Manufacturer Reputation: Choose a reliable steel brand known for consistent quality and performance.

-

Testing Reports: Ask for lab reports indicating tensile strength, elongation, and chemical composition.

-

Rib Design: Ensure the ribs are uniform and deeply engraved for strong bonding.

Top Brands Offering 550 Grade TMT Bars in India

-

Agni Steels

-

TATA Tiscon

-

JSW Neosteel

-

SAIL

-

Vizag Steel

-

Kamdhenu

These manufacturers offer high-quality 550 Grade TMT bars suitable for various applications.

Conclusion

Choosing the right TMT bar is crucial for ensuring the safety, longevity, and strength of your construction project. 550 Grade TMT bars strike the perfect balance between strength and flexibility, making them ideal for modern construction demands. Whether you’re building a multi-storey apartment, a commercial building, or a bridge, these bars offer unmatched durability, structural safety, and cost-effectiveness.

If you’re planning a project and want to invest in materials that will stand the test of time, Fe 550 TMT bars are undoubtedly a smart choice.

by agnisteels | May 9, 2025 | Others

When it comes to constructing buildings that stand the test of time, choosing the right materials is critical. Among these materials, Quality Fe 500 steel bars have become the industry standard for strength, safety, and durability. These bars are widely used in residential, commercial, and infrastructure projects across India and the globe.

What Are Fe 500 Steel Bars?

Fe 500 is a grade of Thermo-Mechanically Treated (TMT) steel bars. The “Fe” stands for iron, and “500” refers to the minimum yield stress in N/mm². This grade is engineered to provide high strength and ductility, making it suitable for both ordinary and complex construction projects. These bars comply with IS 1786 standards set by the Bureau of Indian Standards (BIS), ensuring reliable performance.

Strength and Durability

The most important benefit of Fe 500 bars is their exceptional tensile strength. With a yield strength of 500 N/mm², these bars can withstand significant stress and pressure. This makes them ideal for high-rise buildings, bridges, dams, and other structures requiring heavy reinforcement.

Additionally, Fe 500 bars offer high elongation, meaning they can bend or stretch under load without breaking. This is especially beneficial in seismic zones, as the bars absorb and dissipate energy, reducing the risk of structural failure during earthquakes.

Corrosion and Fire Resistance

Fe 500 TMT bars are manufactured using advanced quenching and tempering technology. This gives the outer layer a tough, tempered martensitic structure while retaining a ductile core. The result is a corrosion-resistant and fire-resistant steel bar that performs reliably in harsh environments, including coastal and high-humidity regions.

Fire safety is a critical concern in building construction. Fe 500 bars can withstand temperatures up to 600°C without losing their structural integrity, offering additional protection in case of fire incidents.

Cost Efficiency

While high-quality construction materials often come with a premium price tag, Fe 500 bars offer excellent value for money. Their durability and low maintenance requirements reduce the long-term cost of the structure. Also, due to their high strength, lesser quantity is required compared to lower-grade steel, which results in overall material savings.

Compatibility With Concrete

Fe 500 steel bars have superior bonding strength with concrete, thanks to their ribbed surface. This ensures that the steel and concrete act as a single unit under stress, enhancing the structural stability and lifespan of the building. The bars are also easy to weld, bend, and cut, making them highly adaptable on the construction site.

Eco-Friendly and Sustainable

Steel is one of the most recyclable materials available, and Fe 500 bars are no exception. Using these bars helps reduce the carbon footprint of construction projects. Many manufacturers also use eco-friendly production processes, adding another layer of sustainability to your build.

Conclusion

Fe 500 steel bars are a smart investment for anyone involved in construction, whether it’s a small residential project or a large-scale commercial development. They offer the perfect blend of strength, flexibility, durability, and safety. Backed by industry standards and engineered using advanced manufacturing processes, Fe 500 bars help build structures that last for generations.

If you’re looking for high-quality Fe 500 steel bars in Chennai or anywhere in India, make sure to source them from a reputed manufacturer like Agni Steels, known for consistent quality and reliability.