by agnisteels | Aug 5, 2025 | E-commerce

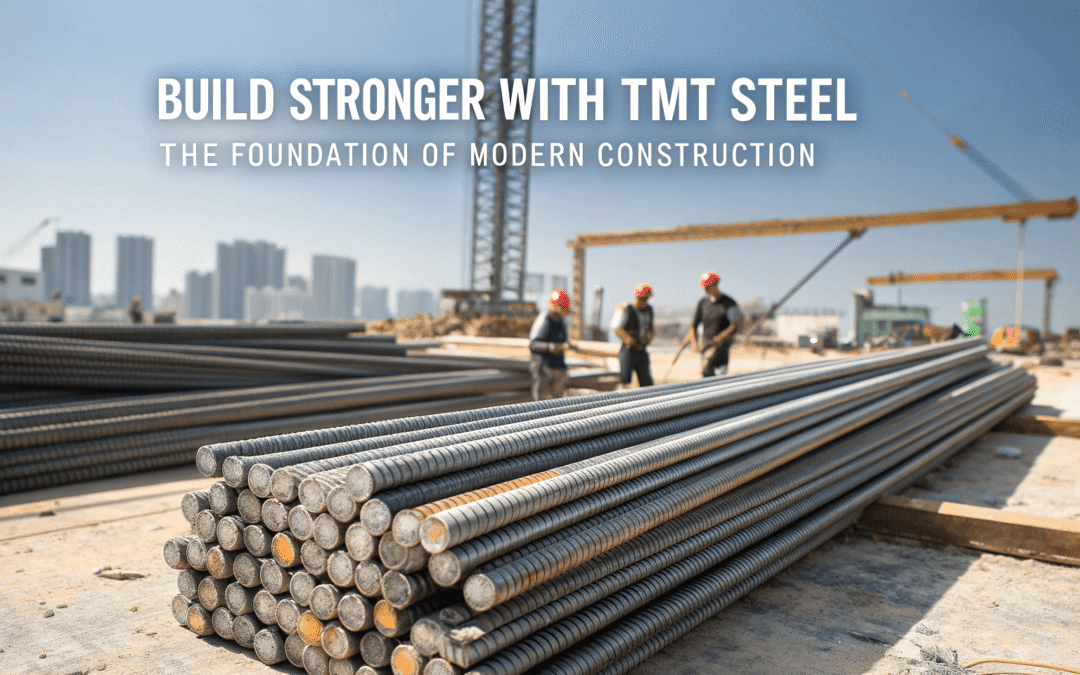

Introduction:

Building your dream home is a lifetime investment—and the strength of that home begins with the right materials. TMT bars, or Thermo-Mechanically Treated bars, play a vital role in reinforcing the structural integrity of your building. Choosing the best TMT bars ensures not only safety but also durability, sustainability, and value for money.

What Makes a TMT Bar the Best for House Construction?

1. Grade and Strength Matters

Look for Fe 500 or Fe 550D grade TMT bars. These offer high tensile strength and ductility, ideal for both low-rise and high-rise structures. The “D” stands for ductility, making them perfect for seismic zones.

2. Corrosion and Fire Resistance

Top-quality TMT bars have anti-corrosive properties and can withstand high temperatures up to 600°C, ensuring long-lasting performance in varied climates.

3. Flexibility and Weldability

Best-in-class TMT bars can be bent easily without breaking and support smooth welding, enabling faster construction without compromising quality.

4. Earthquake Resistance

In earthquake-prone areas, using earthquake-resistant TMT bars is non-negotiable. Their high elongation properties absorb shock without collapsing the structure.

5. Certification and Brand Trust

Choose bars that meet BIS standards and are ISO-certified. Brands like Agni Steels, Tata Tiscon, and JSW are trusted across India for their consistent quality.

How to Identify High-Quality TMT Bars?

-

Check for the brand logo and grade on each bar.

-

Verify BIS certification on the product.

-

Conduct a simple bend test (or ask for one) before purchase.

-

Use digital tools like steel weight calculators to avoid fraud in quantity.

Cost vs. Quality: Why the Cheapest is Not the Best

It’s tempting to save on material costs, but inferior quality TMT bars can lead to higher repair and maintenance costs in the future—not to mention safety risks. Always balance cost with performance.

Conclusion: Build It Right from the Start

The foundation of your home starts with the quality of TMT bars. Choose right today to avoid regrets tomorrow. For homes that last generations, invest in the best.

by agnisteels | Jul 31, 2025 | Household

In 2025, the construction industry continues to evolve at a rapid pace—and so do material costs. Among the most essential elements of modern construction is steel, especially TMT bars, which form the backbone of reinforced concrete structures. Staying updated with the current steel rates and understanding the importance of corrosion-resistant 550D TMT bars can help builders, contractors, and homeowners make better decisions.

Current Steel Rates Update – July 2025

Steel prices in India are influenced by a variety of factors including global demand, raw material costs, transportation charges, and government policies. As of July 2025, the average steel rate for TMT bars across major cities like Chennai, Bengaluru, Hyderabad, and Delhi is as follows:

| City |

TMT Bar Rate (Fe 550D, Per Kg) |

| Chennai |

₹62 – ₹66 |

| Bengaluru |

₹61 – ₹65 |

| Hyderabad |

₹60 – ₹64 |

| Delhi |

₹63 – ₹67 |

Note: Rates are indicative and may vary daily based on market conditions.

Why Choose Corrosion Resistant 550D TMT Bars?

While price is important, quality is critical—especially in coastal or humid regions. That’s where corrosion-resistant 550D TMT bars come into play.

Key Features of 550D TMT Bars:

-

High Ductility: The “D” in 550D stands for ductility, making these bars more flexible and earthquake-resistant.

-

Superior Corrosion Resistance: Ideal for construction in coastal and high-humidity areas where traditional steel corrodes faster.

-

Consistent Quality: Manufactured under strict process control using Thermo-Mechanical Treatment (TMT).

-

Cost-Effective in the Long Run: Reduced maintenance and longer lifespan reduce the total cost of ownership.

Rising Demand for Corrosion-Resistant TMT Bars in 2025

The demand for corrosion-resistant Fe 550D bars has seen a sharp rise this year, especially from sectors like:

Manufacturers like Agni Steels, Tata Tiscon, and JSW are focusing on producing advanced grade 550D bars with anti-corrosive coatings to meet this surge in demand.

Tips Before You Buy TMT Bars

-

Check for Certification: Always buy ISI and BIS-certified TMT bars.

-

Compare Rates: Use current steel rate updates to negotiate better prices with local dealers.

-

Ask for Corrosion Protection: Especially if your construction site is in a coastal or flood-prone area.

-

Buy from Trusted Manufacturers: Ensure consistent quality and support.

Stay Updated with Daily Steel Rates

Whether you’re planning a large commercial project or building your dream home, keep an eye on daily steel rate updates from verified suppliers or industry sources. You can subscribe to newsletters, join WhatsApp dealer groups, or follow trusted brands like Agni Steels for real-time pricing updates and offers.

Conclusion

In the world of construction, timely decisions make all the difference. The current steel rates update helps you plan your purchase better, while opting for corrosion-resistant 550D TMT bars ensures your structure stands strong for decades.

If you’re looking for high-performance TMT bars that offer both strength and longevity, 550D with corrosion resistance is the future-proof choice in 2025.

by agnisteels | Jul 23, 2025 | Others

Introduction

In the ever-evolving landscape of infrastructure and real estate, the backbone of any structure is its steel reinforcement. TMT (Thermo Mechanically Treated) bars have revolutionized the construction industry with their unmatched strength, flexibility, and corrosion resistance. With India emerging as a global construction hub, the demand for reliable TMT bars manufacturers in India has surged. This blog walks you through everything you need to know—from key features of premium TMT bars to choosing the right manufacturer for your next construction project.

What Are TMT Bars?

TMT bars are steel bars that undergo a thermomechanical process to enhance their strength and flexibility. These bars are widely used in RCC (Reinforced Cement Concrete) constructions for residential, commercial, and industrial buildings. The unique manufacturing process gives them high tensile strength while maintaining ductility—making them ideal for earthquake-prone zones and coastal areas.

Key Features of Quality TMT Bars

-

High Yield Strength

Fe 500 and Fe 550D grade TMT bars offer high yield strength, essential for high-rise buildings and heavy infrastructure projects.

-

Corrosion Resistance

TMT bars with a rust-resistant coating or corrosion-resistant elements like copper, chromium, and phosphorus extend the life of your structure.

-

Earthquake Resistance

Their superior ductility and elongation make them ideal for earthquake-prone areas, reducing the chances of structural collapse.

-

Weldability

Good quality TMT bars allow easy bending and welding without losing strength, ideal for custom construction designs.

Types of TMT Steel Bars

-

Fe 415: Suitable for small-scale residential construction.

-

Fe 500: Ideal for medium-rise buildings and general construction.

-

Fe 550 & Fe 550D: Best for heavy-load infrastructure like bridges, dams, and high-rises.

-

Fe 600: Used in industrial and mega infrastructure projects.

What Is Fe 550 TMT Steel Bar?

Fe 550 is one of the high-strength TMT steel bar variants, primarily used in high-rise buildings and heavy-load structures.

-

‘Fe’ stands for the iron content in the bar.

-

‘550’ represents the minimum yield strength of 550 N/mm².

Fe 550 offers greater load-bearing capacity with lower steel consumption, making it cost-efficient and strong.

Why India is a Global Hub for TMT Bar Manufacturing

India is home to some of the world’s largest steel producers and exporters. With growing infrastructure development, smart cities, and housing projects under schemes like Pradhan Mantri Awas Yojana, the TMT bars manufacturers in India have rapidly evolved in terms of quality, production capacity, and innovation.

Top Regions in India for TMT Bar Manufacturing

-

Chennai – Known for corrosion-resistant bars for coastal constructions.

-

Raipur & Durgapur – Major steel belt with advanced rolling mills.

-

Maharashtra & Gujarat – Strategic hubs for supply across India.

-

Punjab & Himachal Pradesh – Suppliers for northern hilly and seismic zones.

Qualities to Look for in a TMT Bars Manufacturer

-

Certification – ISO, BIS, and TUV certifications ensure quality and compliance.

-

Grade Availability – A good manufacturer offers various grades like Fe 500, Fe 550, and Fe 550D.

-

Distribution Network – Reliable brands have a strong pan-India supply chain.

-

Customization Options – Some offer custom sizes, cut & bend options.

-

EEAT Factors – Brands focusing on expertise, safety assurance, and transparency in manufacturing build long-term trust.

Top Benefits of Buying From Reputed TMT Bars Manufacturers in India

Recommended Use of TMT Bars by Structure

| Structure Type |

Recommended TMT Bar Grade |

| Residential Buildings |

Fe 500 |

| High-Rise Towers |

Fe 550D |

| Dams & Bridges |

Fe 550 or Fe 600 |

| Industrial Warehouses |

Fe 500 |

| Coastal Projects |

CRS TMT Bars |

FAQs

Q1. Which is the best TMT bar grade for house construction?

A: Fe 500 is widely considered the best for residential buildings due to its ideal balance of strength and flexibility.

Q2. What makes Fe 550D better than Fe 550?

A: Fe 550D has higher ductility, which improves earthquake resistance without compromising strength.

Q3. Are Indian TMT bars suitable for export?

A: Yes, many Indian TMT manufacturers export to Southeast Asia, Africa, and the Middle East due to global-standard quality.

Conclusion

When it comes to the structural integrity of your dream home or commercial project, never compromise on quality. Choosing from the best TMT bars manufacturers in India ensures long-lasting durability, high performance, and peace of mind. Whether you’re looking for Fe 500 for a home or Fe 550D for a high-rise, make sure your supplier ticks all the boxes—quality, certification, and trust.

by agnisteels | Jul 21, 2025 | Household

In the ever-evolving world of construction, choosing the right materials can determine the strength, safety, and longevity of a building. One of the most essential materials in any structure is the steel reinforcement bar, commonly known as the TMT bar. Among the different grades available, Fe 500 TMT bars strike the perfect balance between strength and flexibility, making them a preferred choice for builders and engineers across India.

Let’s explore what makes Fe 500 TMT bars the gold standard for construction.

What is Fe 500 TMT Bar?

TMT (Thermo Mechanically Treated) bars are high-strength reinforcement bars with a soft inner core and a tough outer surface. The “Fe 500” denotes the yield strength of the bar – 500 N/mm² – which means it can withstand very high stress before deforming. This grade is commonly used in residential, commercial, and infrastructural projects.

Key Features of Fe 500 TMT Bars

1. High Tensile Strength

Fe 500 TMT bars provide excellent tensile strength that allows them to bear heavy loads without breaking. This is crucial in high-rise buildings, bridges, and other structures exposed to dynamic stress.

2. Ductility and Flexibility

Despite being strong, Fe 500 bars are ductile enough to bend without breaking. This makes them ideal for seismic zones where flexibility is vital to absorb shock during earthquakes.

3. Corrosion Resistance

Fe 500 bars, especially when manufactured by reputed brands like Agni Steels, undergo corrosion-resistant treatment. This makes them perfect for use in humid, coastal, or flood-prone areas.

4. Weldability

These bars have low carbon content, which makes welding easier and safer without affecting strength. This reduces fabrication time and cost.

5. Cost Efficiency

Because of their superior strength, fewer Fe 500 bars are needed to achieve the same level of support as lower-grade bars. This leads to a reduction in steel consumption and construction costs.

Applications of Fe 500 TMT Bars

Fe 500 TMT bars are widely used in:

-

Residential homes and apartment complexes

-

Commercial buildings and malls

-

Industrial structures and warehouses

-

Bridges and flyovers

-

Dams, tunnels, and irrigation structures

Their versatility and strength make them a go-to choice for any load-bearing structure.

Choosing the Right Fe 500 TMT Bar Manufacturer

While Fe 500 is a standard, not all TMT bars are made equal. When selecting a TMT bar supplier, consider:

Brands like Agni Steels ensure every bar meets rigorous testing standards, delivering consistency and safety across all their products.

Final Thoughts

Fe 500 TMT bars are a smart and future-ready choice for builders and engineers who don’t want to compromise on quality. Whether you’re building a home or a high-rise, investing in premium-grade steel bars like Fe 500 will provide the structural integrity and durability your project needs.

Always choose certified and reliable TMT bar manufacturers in India to ensure your construction stands the test of time.

by agnisteels | Jul 16, 2025 | Others

The world of construction has evolved significantly over the last few decades. Gone are the days when buildings relied solely on bricks and cement. Today, modern building materials are driving innovation, improving structural integrity, increasing energy efficiency, and reducing environmental impact.

Whether you’re planning a residential project or a commercial skyscraper, the use of advanced materials is no longer a luxury — it’s a necessity.

1. TMT Steel Bars

Thermo Mechanically Treated (TMT) bars are the foundation of most modern RCC structures. Offering high strength, flexibility, and corrosion resistance, TMT bars — especially Fe 550D grade — are essential for buildings in seismic and coastal regions. They bond well with concrete and ensure long-lasting structural support.

2. AAC (Autoclaved Aerated Concrete) Blocks

AAC blocks are lightweight, energy-efficient alternatives to traditional bricks. Made from natural raw materials like fly ash and lime, they offer better thermal insulation, reduce dead load, and are easy to work with. They’re especially popular in urban construction projects that prioritize sustainability.

3. Glass Fiber Reinforced Concrete (GFRC)

GFRC is a high-performance material made from cement, fine aggregate, water, chemical admixtures, and glass fiber. It is used for facades, decorative panels, and architectural features, offering both strength and aesthetic appeal.

4. uPVC Windows and Doors

Unplasticized Polyvinyl Chloride (uPVC) is increasingly being used in modern construction for windows and doors. It’s resistant to moisture, corrosion, and termites, and also offers excellent insulation against heat and noise.

5. Smart Insulation Materials

Materials like spray foam insulation, aerogel panels, and reflective coatings help maintain indoor temperatures and reduce HVAC costs. These materials are now a key part of green buildings and energy-efficient home designs.

Why Modern Materials Matter

Using the right modern materials in construction ensures:

Final Thoughts

As urbanization increases and environmental concerns grow, the adoption of modern building materials is the way forward. From TMT bars to AAC blocks and beyond, today’s materials are designed to meet the demands of smart, strong, and sustainable construction.